Bruker Alicona at EMO 2023

At EMO 2023, Bruker Alicona will present its latest developments for automated measurements of precision dies and edge preparation on round tools live for the first time. To be found from September 18 to 23 in Hall 6, Booth C09.

Edge preparation, a fundamental process in precision engineering, holds immense significance in enhancing the quality of round tools. By carefully shaping and refining the cutting edge of tools like drills, drills with shaft, end mills, and reamers, edge preparation eliminates imperfections, reduces tool failure, and optimizes performance. The process not only extends tool lifespan but also improves machining accuracy, surface finish, and productivity. Embracing edge preparation empowers manufacturers to unleash the full potential of their round tools, achieving unparalleled precision and competitiveness in today's demanding manufacturing landscape.

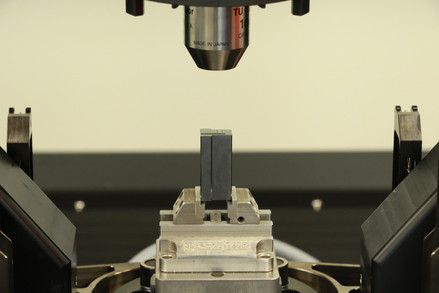

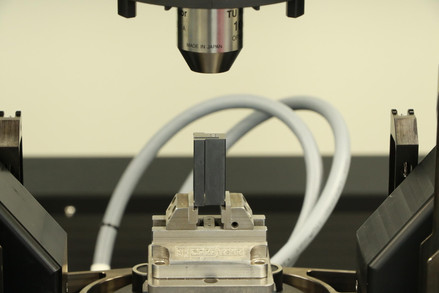

Bruker Alicona's automatic measuring system for edge preparation revolutionizes the process with just three simple steps. The stock tool is securely clamped in the rotary unit, followed by automatic alignment to the CAD model using MetMaX, the company's proprietary software. Operators can effortlessly select the desired edges for automatic measurement and evaluation, streamlining the entire process.

Bruker Alicona's 3D optical measurement systems for the precision die industry are just as exciting as they are for edge rounding. By introducing automated measurement solutions for stamping dies, punching and bending tools, the company enables manufacturers to achieve unprecedented levels of accuracy, efficiency and reliability in their manufacturing processes.

Tactile measuring technologies often reach their limits in precision die manufacturing in terms of accuracy. However, resolution, measurement duration and two-dimensional evaluations are also not up to the demands of this quality-driven industry. Bruker Alicona's optical 3D measurement systems, on the other hand, provide turnkey, automated solutions with manufacturing tolerances in the single-digit µm range.

The in-house MetMaX software ensures excellent usability during the teach-in process, further enhancing the system's appeal to industry partners. Industry collaborators, including TE Connectivity, Stepper, Kleiner and Hailtec, have praised the future-proofing of the Bruker Alicona solution, which offers full compatibility with PMI.

With Bruker Alicona, we are already able to automatically start and execute the measurement process in our production. We are currently working on enabling networking with other machines so that the machine parameters are automatically and continuously adjusted based on the measurement results.

Download official press release: