How to measure smallest components with highest precision

As a manufacturer of precision components for watches or other precision devices you are challenged by high quantity output and highest quality at the same time. Very high demands are placed on all components in terms of dimensional accuracy. This applies to gears, shafts and rivets as well as to injection molded plastic parts.

Benefit from Bruker Alicona's optical 3D measurement solutions for the quality control of your precision components and determine dimensional accuracy, GD&T features and surface quality with a single system. With Vertical Focus Probing technology, users can optically probe components laterally and over the entire surface for the first time. This also enables the measurement of holes or bores with a diameter-to-depth ratio of 1:3 to 1:10.

Do you have questions?

Our applications for precision manufacturing

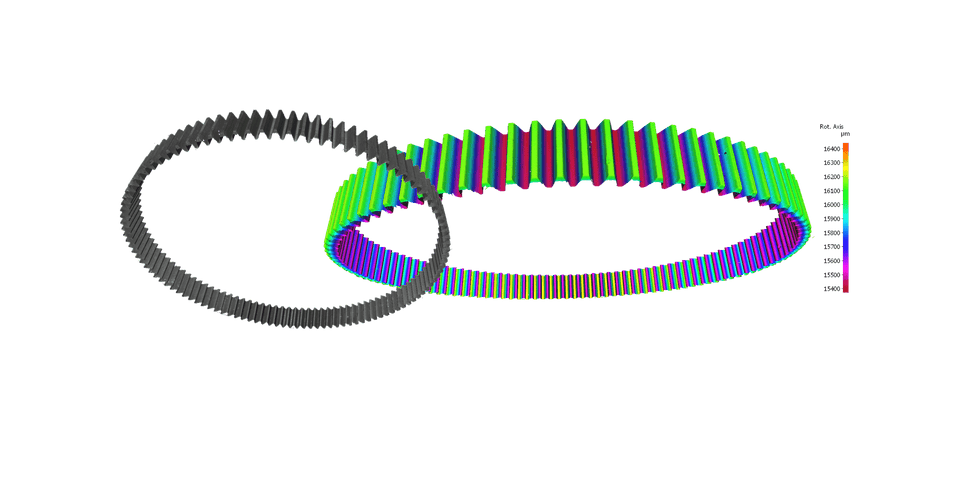

The following measurements can be performed for the analysis of the relevant components, such as micro gears:

- Area based measurements & verification of entire tooth flanks

- Measurements of complex shapes with small radii and angles, even at high measurement volumes

- Determination of shape and roughness via large lateral and vertical scanning areas within one single measurement run

- Verification of dimensional accuracy and finish quality

- Measurement of composites from various materials, even with reflective properties

- Failure analysis, incoming goods inspection and integrated tools compensation

- 3D measurements of dies

- Quality assurance in stamping and forming technologies

The range of applications is growing. If you have a measuring task, please contact us.

Together we will find a solution that meets your requirements!

Discover more about optical 3D metrology & measurement in the precision manufacturing

Our product highlights for the precision manufacturing industry

Lecture: Higher efficiency & function prediciton in micro gearing

The production of micro components with tolerances of only a few μm represents a major challenge for manufacturing. That's why the teams from wbk Institute of Production Science at KIT in Karlsruhe, Germany, and Dentsply Sirona aim at optimizing the quality assurance of micro gears. In this project, the µCMM from Bruker Alicona is used for in-line metrological acquisition during micro gear production.