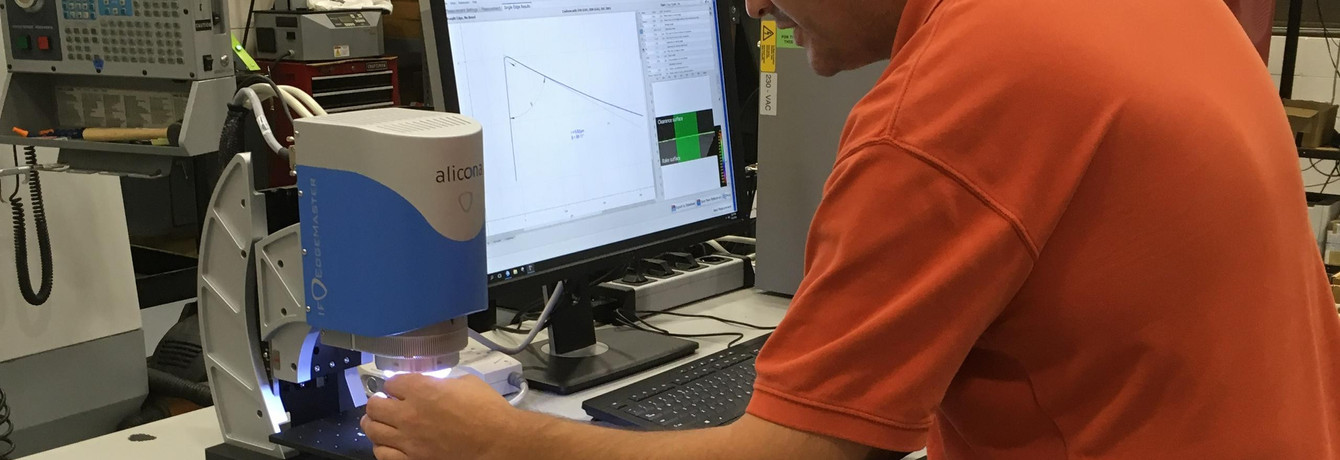

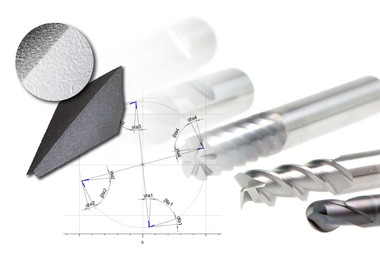

High-resolution, fully automatic measurement of tool cutting edges in production

The EdgeMaster series includes the Edge Master, EdgeMasterX and EdgeMasterHOB tool measuring systems. The measuring systems are used for high-resolution, fully automatic measurement of tool cutting edges in production. Whether you use an EdgeMaster in the measuring room or on the shop floor does not change the result: The measurements are high-resolution and robust even in the presence of vibrations, extraneous light and temperature fluctuations.

Technical specifications

| Measurement principle | non-contact, optical, three-dimensional, based on Focus-Variation | |

| Positioning volume (X x Y xZ) | RL objectives: man.: 25 mm x 25 mm x 155 mm (Z: 25 mm mot., 130 mm man.) = 96875 mm3 | |

| SXRL/AXRL objectives: man.: 25 mm x 25 mm x 120 mm (Z: 25 mm mot., 95 mm man.) = 75000mm³ |

| Objective magnification | 10x | 20x | 50x | 2xSX | 4xAX | 10xAX | 20xAX | 50xSX | |

| Working distance | mm | 17.5 | 16 | 10.1 | 34 | 30 | 33.5 | 20 | 13 |

| Lateral measurement range (X,Y) | mm | 2 | 1 | 0.4 | 10 | 5 | 2 | 1 | 0.4 |

| (X x Y) | mm² | 4 | 1 | 0.16 | 100 | 25 | 4 | 1 | 0.16 |

| Vertical resolution | nm | 100 | 50 | 20 | 3500 | 430 | 130 | 70 | 45 |

| Min. measurable roughness (Ra) | µm | 0.3 | 0.15 | 0.08 | n.a. | n.a. | 0.45 | 0.25 | 0.15 |

| Min. measurable roughness (Sa) | µm | 0.15 | 0.075 | 0.05 | n.a. | n.a. | 0.25 | 0.1 | 0.08 |

| Min. measurable radius | µm | 5 | 3 | 2 | 20 | 12 | 5 | 3 | 2 |

More measurement systems of the EdgeMaster series

EdgeMasterX

Verify multiple edges in one measurement run

The EdgeMasterX is part of the Bruker Alicona product range for optical, high-resolution tool measurement in production and an extension of the EdgeMaster. The EdgeMasterX allows users to verify multiple edges in just one measurement run.

Additional functions of the EdgeMasterX:

- measurement of different edge parameters on different positions of a tool or

- measurement of user-defined parameters on tools of a batch

- In combination with a rotation unit, chamfered cutting edges of a tool are also detected in only one measuring run.

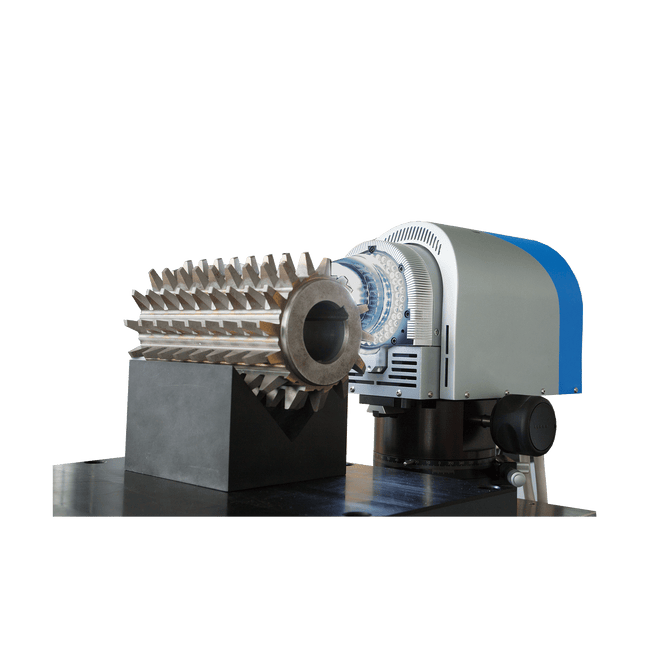

EdgeMasterHOB

Optical cutting edge measuring device for hobs

The EdgeMasterHOB is one of Alicona´s optical tool measurement systems and a market-specific adaption of the optical cutting edge measurement system EdgeMaster. Like all Alicona tool measurement systems, the EdgeMasterHOB is used for automated quality assurance. The hob measuring device is particularly applied in e.g. regrinding centers. A working distance of 33 mm allows effortless measurement of cutting edges even in areas that are hard to access.

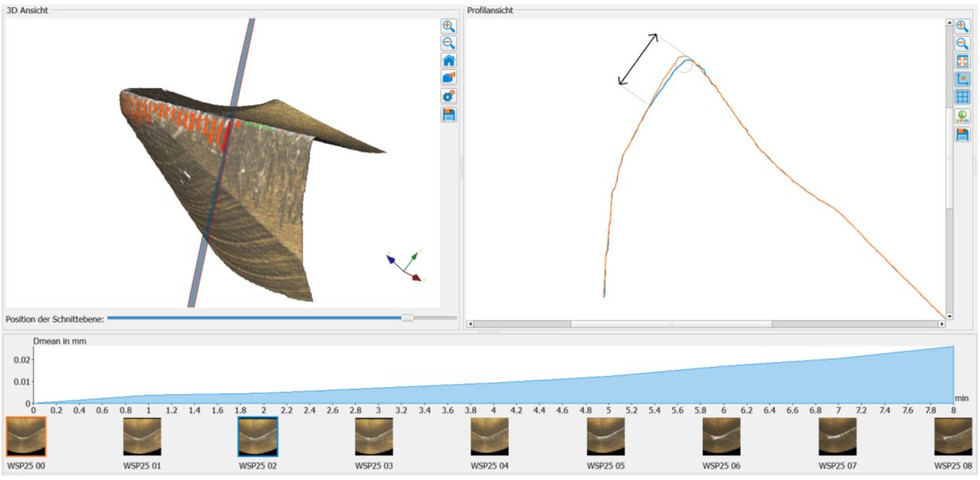

Users measure, amongst other features:

- chipping and edge defects

- chamfer as well as edge roundness at the tooth flank, tooth root and tooth tip