More control for your production lines thanks to optical 3D measurements

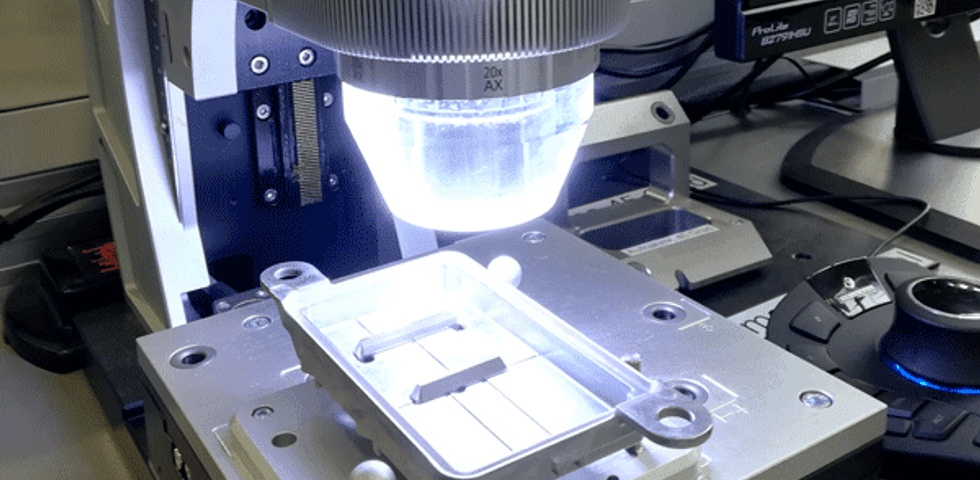

As a manufacturer for the automotive industry, you need to deliver the best quality for high-end manufacturing, relying on high measuring accuracy and a significant reduction in the reject rates of your components. Both are decisive factors to increase your production efficiency in inline or near-line production. Achieve higher frequency in sampling as well as faster inspection times with our optical 3D measurement systems. We will support you to get more control over your production lines while delivering high-quality components to your customers.

Do you have questions?

Applications for the automotive industry

How Bruker Alicona measurement systems can support you:

- 3D measurements of fuel injection nozzles, valves, connecting rods and envelopes

- High-resolution measurements of valve seat roundness

- Automatic cam inspection to evaluate ridges and distance between laser lines

- Failure analysis and development of materials for engine and transmission components

- Quality assurance of sealing systems, synchronizer rings, car bodies and steel surfaces

You have a measurement task that is not on the list? Just contact us. Together we will find a solution that meets your requirements.

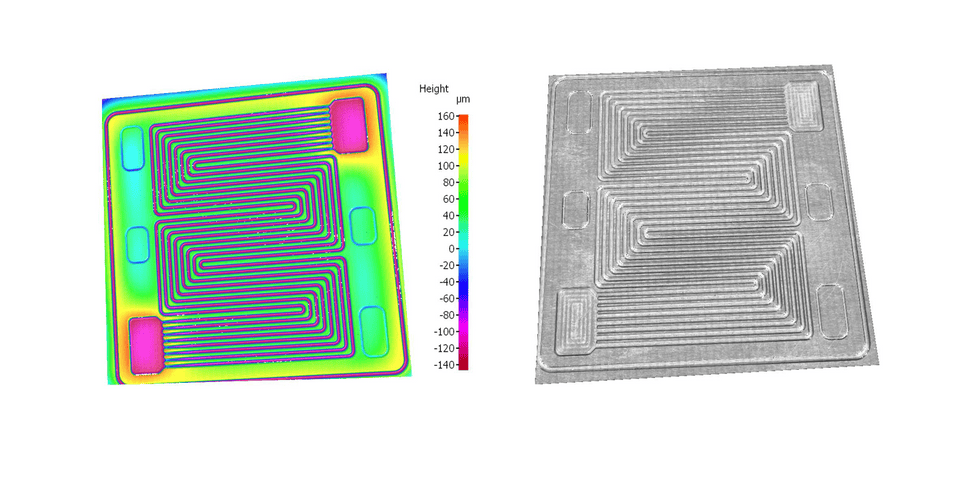

Bipolar Plates

Nozzles & Needles

Valve seats

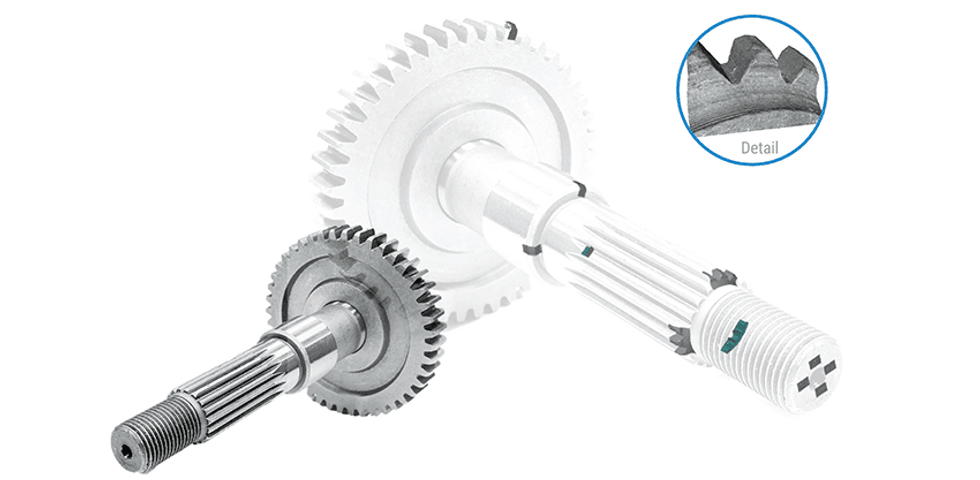

Gears

Pumps

Cam & Conrods

Many more applications!

Electrical plugs, small electro motors, sensors, battery seat, pumps and turbo components, etc.

We will find a solution for your measurement task. Get in touch with us!