How to shorten machining times and extend the service life of your cutting tools

You want high quality cutting tools with excellent performance and tool life, but you are always confronted with cutting edge defects, rapid wear, long machining times or unsatisfactory results on the workpiece? Testing and continuous measurement in research and production is the only solution for manufacturers to produce cutting tools according to ever-increasing customer demands for tolerances and performance.

Shorten machining times and extend the service life of your cutting tools effortlessly by integrating our cutting-edge technology into your quality control processes. Benefit from the power of Focus-Variation to accurately measure dimensional accuracy and surface finish with unparalleled precision - all with a single system.

Do you have questions?

Our applications for the cutting tool industry

Here you can see for which applications Bruker Alicona optical 3D metrology is used.

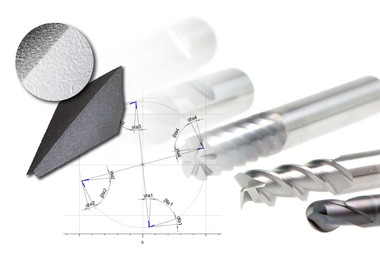

The following measurements can be performed for the analysis of the relevant components: e.g.

- Roughness measurement

- GD&T measurement (form/geometry)

- Cutting edge geometry

- Defect measurement

- Wear measurement

- Coating measurement

The range of applications is growing. If you have a measuring task, please contact us.

Together we will find a solution that meets your requirements.

Inserts

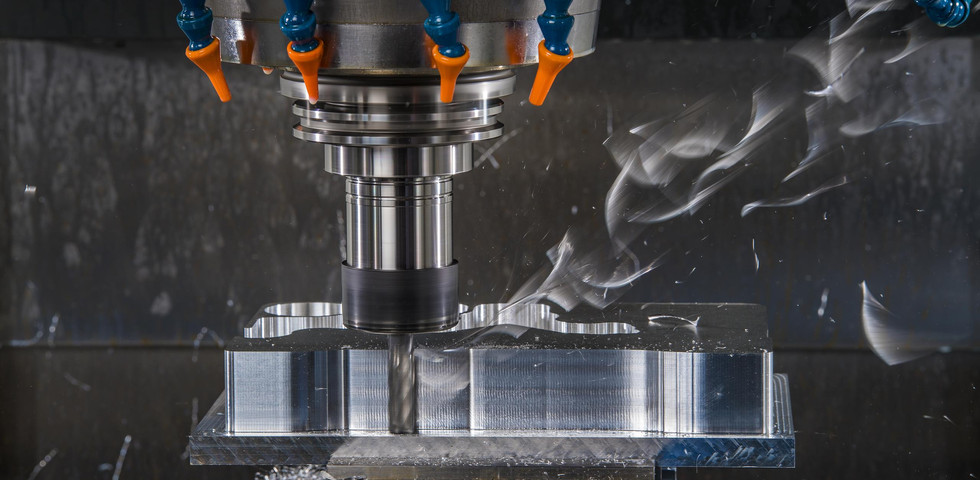

Drills & Mills

Saw blades

Punches

Your application is not included?

We will find a solution for your measurement task. Get in touch with us!

Discover more about optical 3D metrology & measurement in the cutting tool industry

Our product highlights for the cutting tool industry

Lecture: Smoothing, rounding, deburring – how metrology increases efficiency

Soran Jota from OTEC Präzisionsfinish management has been using Bruker Alicona's Focus-Variation for a decade. In this lecture he reports first-hand how the reliability of his processing machines as well as the quality of drill components, milling cutters and gear parts have been optimized by this measurement technology.