Optical 3D measuring systems & devices for your quality assurance

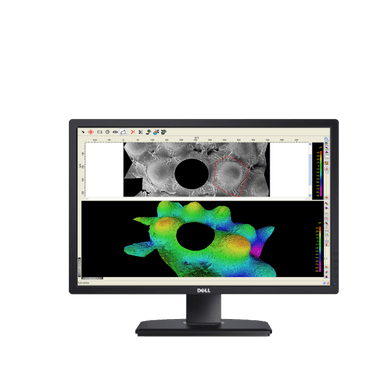

As a manufacturer of optical industrial metrology, we offer a broad portfolio of optical 3D measuring systems & devices to support companies in various industries with precise quality assurance in production. Based on Focus-Variation technology, our measuring systems not only enable surface roughness measurement, but also the detection of micro-geometries, shapes and structures.

Our product range includes:

- Optical coordinate measuring machines

- Optical 3D measuring systems

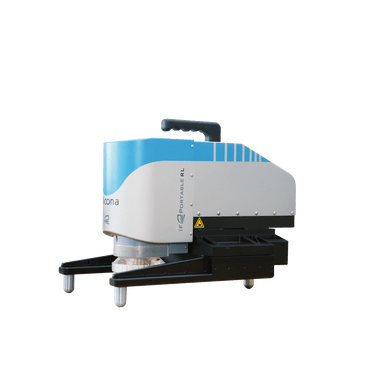

- Portable/mobile measuring devices

- Optical profilometers

- Robot-assisted measurement solutions

These optical 3D measuring devices enable high-precision measurements both in production and in the measuring room.

dieSonne-107-2560x1423-658x366.jpg)

Discover our optical measuring systems designed for production

Learn how our devices contribute to achieving the highest quality standards in manufacturing. Contact us for a personalized consultation to find the optical 3D measuring solution that best suits your application!

Optical 3D measuring systems enable:

- 3D Measurements of dimension, position, shape and roughness with one optical sensor

- Non-contact, non-destructive measurements

- Smooth use in production environments

- Easy operation and one-button solutions

- High-precision measurement results

- Fast detection

We can measure any number of surfaces and surface features in just one measurement process. This not only makes the measurement very precise compared to our previously used measuring device, but also very economical due to the short measuring time.