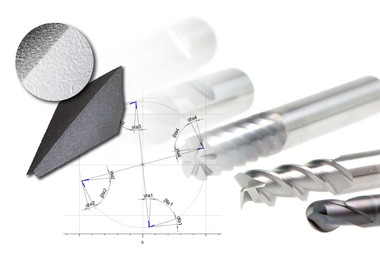

"When it comes to manufacturing complex insert geometries, it's all about the correct tool," emphasizes Alfred Maier, Head of Quality Assurance and Quality and Environmental Management at Boehlerit. "Manufacturing inserts is a cost- and time-intensive process. This means that quality assurance can't apply to the finished tool only," he continues, describing the measurement strategy of the Austrian manufacturer of carbide tools. Alfred Maier's concept of quality assurance starts at the very beginning of the manufacturing process, in mold making. At the Kapfenberg plant in Styria, Boehlerit relies on Bruker Alicona's optical measurement systems in their pressing tool department. The Boehlerit experts in the areas of metallurgy, coating technology, and pressing technology use Bruker Alicona's high-resolution 3D measurement system InfiniteFocus in combination with a motorized rotation unit. This allows them to optimize the clearance between stamp and die, and to measure the complex geometries of inserts in a fully automated repeatable process.

Measurement of dimensional accuracy and surface roughness

"To receive precisely manufactured tools, stamps must be accurate themselves," Alfred Maier explains. For this reason, Boehlerit places a great deal of emphasis on manufacturing ideal stamps for over 6000 different types of inserts at their own pressing tool department. Ideal stamps are produced by ensuring the clearance between stamp and die is as small as possible, as this reduces wear. To accomplish this, Boehlerit uses the InfiniteFocus system to measure the aligned stamp and die, determining the best clearance value. The optical high-resolution measurement system is then employed fur further measurements. Boehlerit verifies post-processing and corrective steps carried out on the pressed raw part to achieve required dimensional accuracy and surface roughness.

Reduction of post-processing and refining

Naturally, the best and most economical scenario for Boehlerit's quality assurance is if little to no post-processing or corrections are necessary, as refining steps such as grinding are expensive. In this respect, the InfiniteFocus system combined with a motorized rotation unit has already paid off for the company. Thanks to the system, Boehlerit has been able to reduce post-processing significantly and corrective steps have also been rendered much more efficient. This has shortened the overall product development time to be ready for serial production. Alfred Maier explains: "We used to inspect our pressed raw parts with tactile measurement devices. These quickly reached their limits, especially when it came to measuring complex geometries. The inserts we manufacture today don't have any straight edges anymore. Today´s geometries with undercuts simply can't be mapped with tactile methods."

Shortened development times by more than a third

Meier describes the improvements that have been achieved with optical metrology: "With InfiniteFocus, we are able to manufacture complex geometries far more accurately and require less corrective grinding. For example, we have been able to significantly reduce burrs." Gerhard Melcher, head of segment turning and milling and head of Marketing at Boehlerit, expresses these advancements in terms of numbers: "We used to have product development times of up to 1.5 years. Thanks to InfiniteFocus, we have been able to shorten development cycles by more than a third. Today, despite growing complexity of edge geometries, our machining tools are ready for launch in less than 10 months."

All relevant edge geometries in one measurement cycle

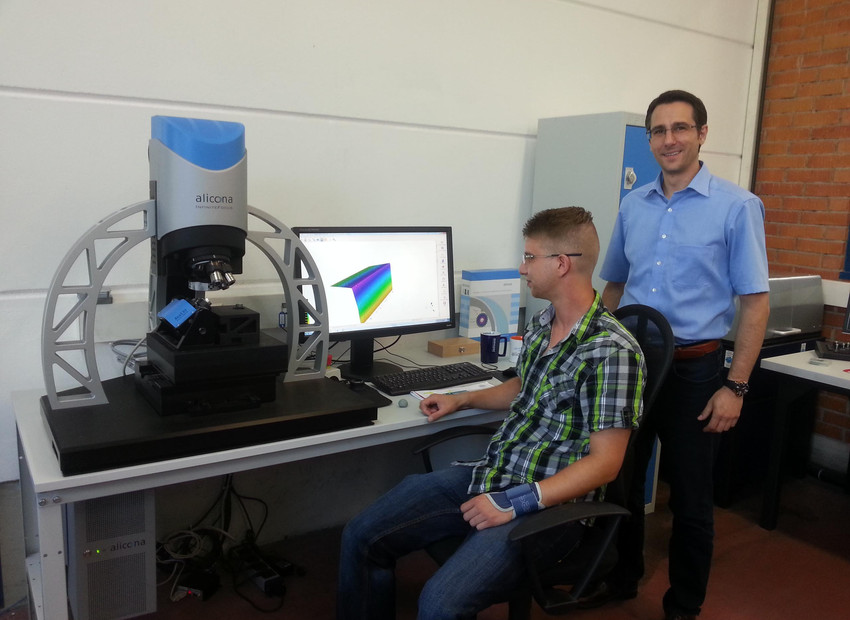

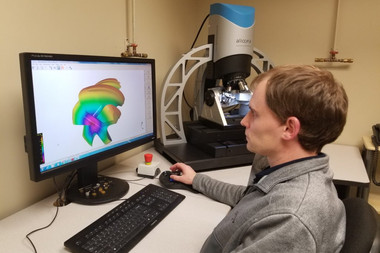

As edge geometries grow in complexity, quality assurance and measurement systems are subject to ever increasing requirements. This translates to enormous pressure on those responsible for quality assurance. "We are expected to work fast and to not keep production waiting. At the same time, measurements need to be precise, valid, and repeatable," Alfred Maier explains. With Bruker Alicona, Boehlerit has found the ideal partner to meet these requirements. The quality assurance department profits greatly from the fully automatic motorized rotational unit. Markus Peihser, measurement technician at Boehlerit, describes the advantages: "The rotation unit allows me to automatically measure all relevant geometries and edge parameters in just one measurement cycle. There is no need for me to reposition the part in the grip.”

High repeatability of measurements

Another feature that quality assurance profits from are the system's capabilities for importing external datasets. These make it possible to automatically measure dimensioning. Additionally, deviations are also displayed graphically. "Undersizes and oversizes are also visualized using a color coding. As a result, we become aware of faults much faster, avoid time-consuming corrections, and accelerate the process as a whole," Peihser points out. The high repeatability of InfiniteFocus's measurements has become another important factor for Boehlerit to boost efficiency. Gerhard Melcher, Head of Marketing: "We are also a supplier and development partner to other tool makers. Our customers demand extensive documentation and repeatability of measurements. Regardless if you measure today or tomorrow, the measurement results have to be the same."

Boehlerit uses Bruker Alicona systems to carry out the following measurements:

- Measurement of the clearance between stamp and die

- 3D measurement of the geometry of pressed raw parts

- Numerical verification of corrective processes and post-processing such as grinding

- Automatic measurement of form deviations

- Full form measurement of the geometry of inserts with Real3D technology