Blog

Artificial Intelligence (AI) is any technique that enables computers to mimic human intelligence by means of logic and machine learning. In the case of optical metrology, automation options have already become indispensable, helping to meet the increasing demand for automation and error minimization in manufacturing. In addition to enhancements in hardware, for example with Collaborative Robots that serve as Pick & Place solutions for automatic placement, measurement and sorting, there are also various software solutions based on AI. For example, they are useful for classification and segmentation of ok/not ok components.Automatic detection of ok/not ok components

The process for automatic classification and segmentation is based on intelligent, self-learning algorithms that serve to segment and classify by characterizing and analyzing components. Surface parameters for component evaluation are automatically derived and evaluated. This evaluation is based on a combination of 2 D texture data and 3 D topography data, which are analyzed during the inspection process. By means of an artificial intelligence training software a classifier is trained based on negative as well as positive examples, which then enable the automatic detection of ok/not ok components.

Some field-proven examples for the use of AI are the analysis of grain distribution on grinding tools or the evaluation of sandblasted or laser-treated components. Another example from, e.g., the aircraft industry, is the evaluation of shot peening processes.

A significant advantage of Artificial Intelligence (AI) technologies is the replacement of time-consuming manual activities in the manufacturing process, which results in faster automation of processes. This is possible because re-programming of new sequences is no longer needed – instead, it can simply be "trained". For users of measurement technology, this also means that measurement ranges no longer must be manually narrowed down on a measurement data set, resulting in minimized subjective misjudgments. In the future, AI will be able to select measuring ranges independently, allowing for automatic planning and creation of measurement programs.

To dive deeper into the topic, watch the lecture on "Automatic defect detection & measurement with AI” by Thomas Lankmair: https://bit.ly/3oMaTao

Want to see how optical 3D metrology and AI are used in practice? Read here how Vitesco (formerly known as Continental Division Powertrain) use AI in a new laser cleaning process.

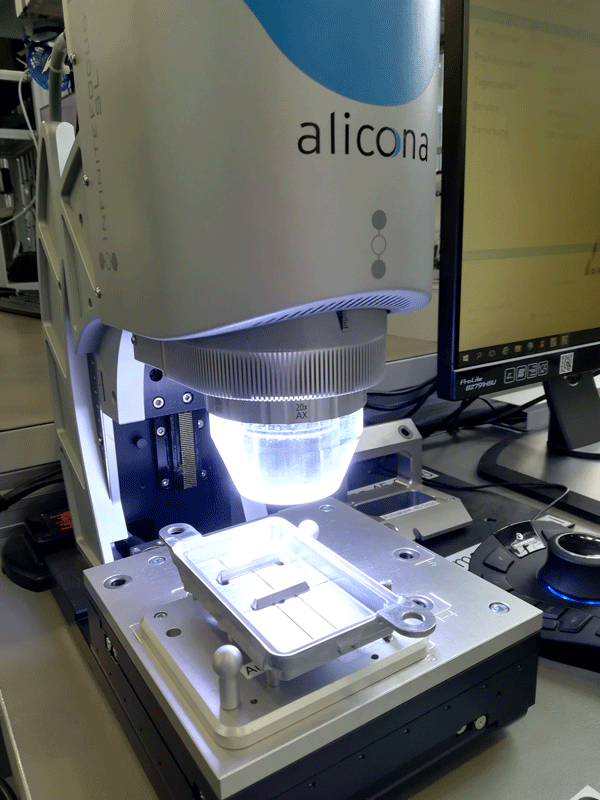

The InfiniteFocusSL measurement system also offers automatic segmentation and classification. At Vitesco, the solution is used for quality control of laser machining processes.

Image Source: ©Vitesco Technologies