Blog

问题是:什么是光学计量学中的人工智能?

人工智能(AI)是使计算机通过逻辑和机器学习来模仿人类智能的任何技术。就光学计量学而言,自动化选项已经变得不可或缺,有助于满足制造业中对自动化和误差最小化的日益增长的需求。除了硬件方面的改进,例如,协作机器人作为自动放置、测量和分拣的取放解决方案,还有各种基于AI的软件解决方案。例如,它们有助于对合格/不合格部件进行分类和分割。

The process for automatic classification and segmentation is based on intelligent, self-learning algorithms that serve to segment and classify by characterizing and analyzing components. Surface parameters for component evaluation are automatically derived and evaluated. This evaluation is based on a combination of 2 D texture data and 3 D topography data, which are analyzed during the inspection process. By means of an artificial intelligence training software a classifier is trained based on negative as well as positive examples, which then enable the automatic detection of ok/not ok components.

Some field-proven examples for the use of AI are the analysis of grain distribution on grinding tools or the evaluation of sandblasted or laser-treated components. Another example from, e.g., the aircraft industry, is the evaluation of shot peening processes.

人工智能(AI)技术的一个显著优势是取代了制造过程中耗时的人工活动,从而更快地实现流程自动化。这是可能的,因为不再需要对新的序列进行重新编程 - 相反,它可以简单地进行 "训练"。对于测量技术的用户来说,这也意味着测量范围不再必须在测量数据集上手动缩小,从而使主观误判降到最低。在未来,人工智能将能够独立选择测量范围,从而实现自动规划和创建测量程序。

要深入了解这一主题,请观看托马斯-朗克迈尔关于 "用AI进行自动缺陷检测和测量 "的讲座:https://bit.ly/3oMaTao

想看看光学三维计量和人工智能在实践中是如何应用的?请 看Vitesco(原名大陆集团动力总成部)如何在新的激光清洗过程中使用AI。

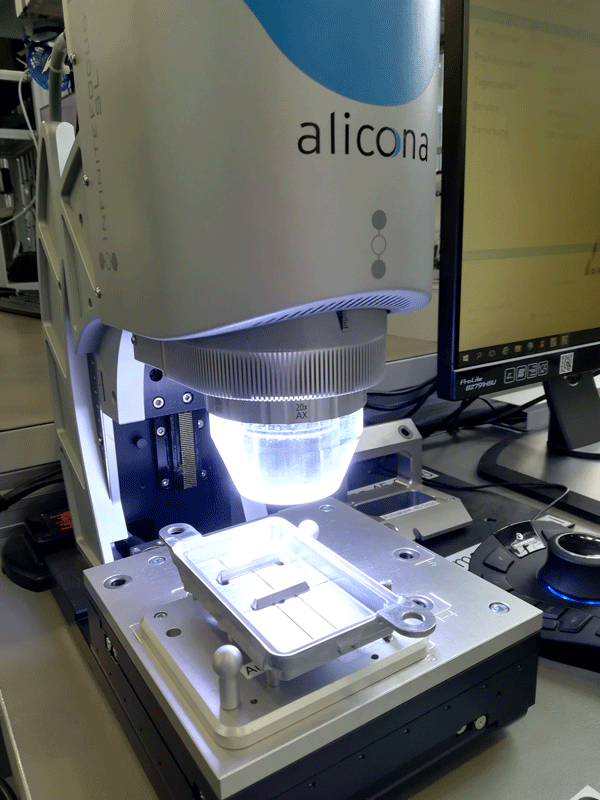

InfiniteFocusSL测量系统还提供自动分割和分类。在Vitesco,该解决方案被用于激光加工过程的质量控制。

图片来源:©Vitesco Technologies