Form & roughness measurements: Practice reports from daily use

In this webinar, you will learn more about current applications in selected key markets such as medical technology, tooling and aerospace. See how the optical coordinate measuring system µCMM, tool measuring system EdgeMaster, and Cobots, a combination of an optical 3D measurement sensor and collaborative robot are used in practice.

In this webinar we present the following applications and systems:

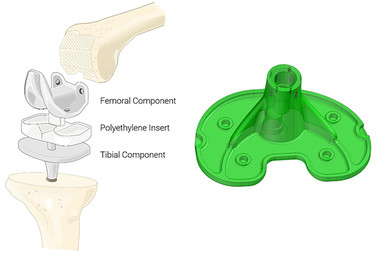

- Medical technology: A customer from the medical technology sector uses the optical µCMM not only for the measurement of high-gloss knee implants but also for the lateral probing of vertical surfaces (Vertical Focus Probing)

- Tooling industry: IMCO, manufacturer of high-performance cutting tools, uses the Bruker Alicona EdgeMaster to measure shape and contour accuracy, rake angle, undercuts, chipping and roughness. Especially the easy handling of the system is an enormous advantage for IMCO.

- Aerospace industry: MTU Aero Engines already has three Cobot systems in operation for break edge measurement. For MTU, the automatic measurement and evaluation of radii, chamfers and break edge on turbine engine components is a criterion of modern quality assurance.

- Expert interview: Dr. Martin Koller from the Clinical Department of Dental Medicine at the Medical University of Graz, Austria, explains how and why the InfiniteFocus optical measuring system is used.

Share this article