"Four features determine the service life and machining result of modern day cutting tools. These are substrate material, coating, macro and micro geometry." Matthew S. Osburn, Vice President & Technical Director of US manufacturer IMCO Carbide Tool Inc. knows what he is talking about. Specialized in the development of milling cutters with multiple flutes, he also knows about the importance of the right measuring technology: "The cutting edge is the wear part of a milling cutter." IMCO views micro geometry as being so critical that they desired a system tailored for only those types of measurements. Recently, the supplier of carbide cutting tools has replaced its existing "outdated device with an upgraded and highly accurate measuring system". Osburn continues: "We are well known for our high level of research and development activities, and reliable verification of edge preparation is of major importance. The most important criteria for the evaluation of suitable measuring systems for us were accuracy and repeatability of the measurements.”

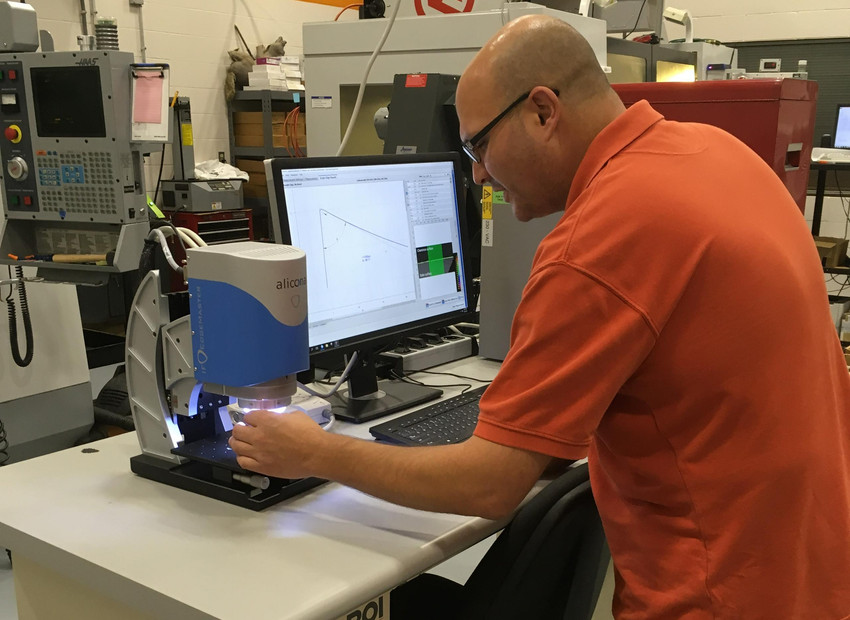

EdgeMaster systems are being used in prototype development as well as in production

In the end, the decision to invest in an Bruker Alicona measuring system for prototype development was an easy one. "I have the utmost confidence in the measurement values the EdgeMaster delivers", Osburn says. However, accuracy is only one advantage that the IMCO Vice President sees in the Bruker Alicona system. "We primarily measured edge hone radius sizes with our old system. With the EdgeMaster, and its ease of use, we now routinely measure many more attributes than before, and we do it quicker and with more confidence in the measurement results.”

As a conclusion, Bruker Alicona has not only met but exceeded all expectations in terms of accuracy, repeatability and reliability of measurements. Only shortly after the investment in its R&D center, the management was so impressed by the easy operation and robustness of the optical measuring system that a second EdgeMaster is now being used in production.

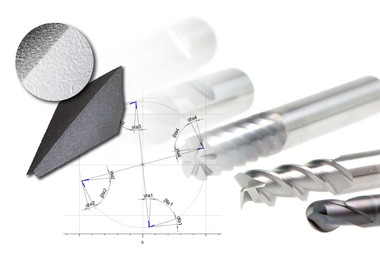

Chipping and surface finish measurement on chip-surface

IMCO´s tool design offers "greater productivity results for very small to very large operations”, as the supplier says. "Higher productivity is due to increased chip flow and elimination of chip packing.” IMCO customers further report on higher metal removal rates and fewer tool changes. All these attributes can be traced back to the supplier´s commitment to the four pillars of a modern cutting tool, one of them being micro geometry and verified by high resolution measurements with Bruker Alicona´s EdgeMaster system. Parameters such as shape and contour accuracy, rake angle, undercuts, chipping and roughness on i.e. the chip surface are decisive for the quality of the cutting edge and thus for the machined workpiece. IMCO offers milling cutters with up to thirteen flutes that achieve above-average surface finish even with materials that are difficult to machine. Development and testing takes place in the internal research and development center, where IMCO can grind, hone, inspect and machine with prototype cutting tools. The EdgeMaster is also used to measure the surface finishes of the flute at various grinding parameters to optimize surface integrity. Osburn further explains: "All tools in prototype development are measured and documented with Bruker Alicona. We then machine with these tools, meticulously logging our machining results. This process enables us to quickly correct the tool geometry if required. The EdgeMaster guides us to developing the highest performance cutting tools on the market.”

"Intensive research is now carried through to the production environment”

Another important aspect in prototyping is the use of a flexible measurement system that enables highly accurate measurements on different tool shapes, types and sizes. IMCO has to measure a wide variety of sizes and helix angles. According to Osburn, it is "easy to cover this wide variety of tools with the EdgeMaster." He sees the right measurement technology as one of the decisive factors in ensuring a steady flow of new products and to improve upon the tools that are already offered. "Focus-Variation is critical to our ongoing success", he says. With a second EdgeMaster in use, the intensive research is now carried through to the production environment.

Simple handling is just as important as measuring accuracy

Measurement accuracy, repeatability and robustness of the Focus-Variation technology in combination with the easy handling of the EdgeMaster system has led to the decision to purchase an additional device in manufacturing. "Our R&D center develops exact specifications for the edge treatment on our high performance cutting tools. Once newly developed tools are released for production, using the same measurement technology as applied in research makes perfect sense”, Osburn explains. "In production, the EdgeMaster is used to verify that the precise edge treatment developed in the R&D is applied to the tools going to our customers.” He is particularly enthusiastic about the ease use of use. "The system worked so well and was so easy to learn that we started training staff on the shop floor. The operators love the new EdgeMaster, it is so easy to learn and use", Osburn says. He is convinced, that "on the shop floor, simple handling is just as important as measuring accuracy. Bruker Alicona understood that 100%.”

75% reduction in the time necessary to take readings on the factory floor

A series of clamping tools for easy fixturing, user friendly controls and single-button solutions to perform measurements create this simple user guidance. High-resolution measurements also at vibrations, extraneous light or temperature fluctuations complete production suitability of the system. According to Osburn, IMCO also gains an advantage for research & development through measurements in production. "It is an additional benefit for our research that we can store all measurements for future reference", he explains. In his view, the EdgeMaster ensures that IMCO customers consistently get end millers with optimal micro geometry. Osburn about the ROI that has been achieved so far: "The Bruker Alicona technology is unique. We have seen a 75% reduction in the time necessary to take readings on the factory floor. Most of this time savings is attributed to the ease of use of the measurement system.”