As an interdisciplinary research institution SPSM works with renowned European partners such as the German Fraunhofer IPA (Fraunhofer Institute for Manufacturing Engineering and Automation) or the UK Future Metrology Hub on the development of new production technologies. The platform regards metrology as one of the necessary key competences to achieve this and operates its own measuring center, the Sino British Center on Smart Metrology and Quality Assurance. This center is characterized by highest possible user-orientation and state-of-the-art technological equipment for project partners and customers from industry. "We want to use high-precision metrology to develop and drive forward new manufacturing technologies," says Metrology Manager Yu Quin about the center's mission. She decides which measurement systems and technologies are applied. "In our measurement center we work with the most established technologies and the most renowned suppliers," she says. An important part of the product range is the measuring service for customers from e.g. tool & mold making, the automotive industry and aviation. They reach out to Yu Quin's team when complex components with smallest surface details and tight tolerances need to be verified. The partnership with Bruker Alicona has been in place since the end of 2019, and the cooperation promises further possibilities and benefits for industry.

Verify dimensional accuracy and roughness with one system

The customers of the Sino British Center on Smart Metrology and Quality Assurance come from all sectors of the manufacturing industry. So, the need for flexible measuring systems that can be used for a wide range of component shapes, sizes and materials is correspondingly high. "Before Bruker Alicona, we worked with a confocal system, but that did not offer this component independence. The working distance was too low, and many components could not be measured with sufficient measurement quality," says Quin. Also compared to tactile measuring systems, she clearly favors the non-contact technology of Focus-Variation. "Some components have such a thin and sensitive coating that we would damage them with a stylus." Apart from a wide range of applications, she sees another advantage in Bruker Alicona measuring equipment. "We now measure both the roughness and the dimensional accuracy of a component with the same measuring system. This also increases our efficiency."

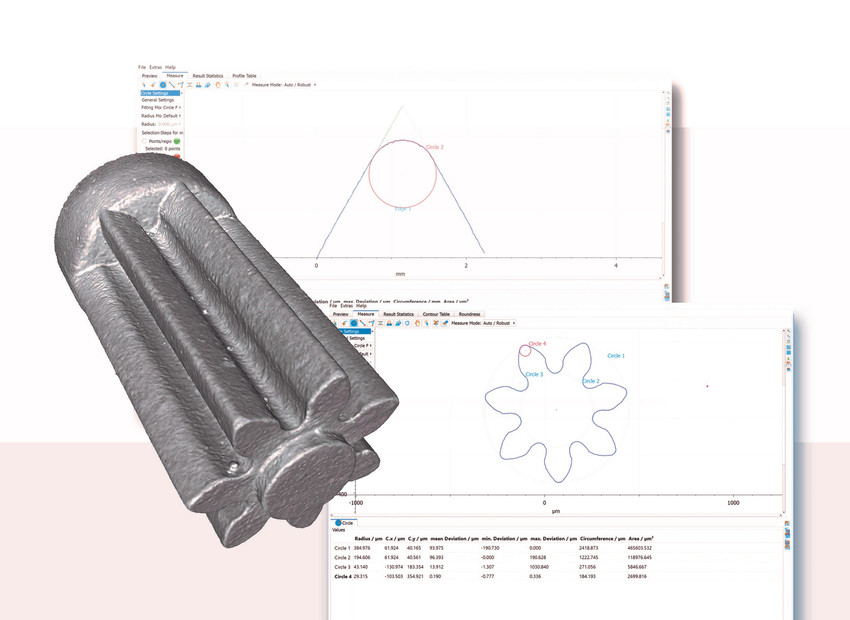

Tool industry: Measuring geometry and roughness of PCD tools

A PCD tool is one of many examples that shows that both surface quality and geometric features have an impact on the functionality of a component. The verification of the shape parameters includes radius, rake, chip and clearance angles as well as chipping. These characteristics determine the tool life of the diamond tool, while roughness parameters on the chip and clearance surface have a significant influence on the surface quality of the machined workpiece. Here, Bruker Alicona offers the ideal solution: The high resolution in combination with the area-based Focus-Variation principle enables the traceable measurement of the smallest surface details. This also applies to the complex geometric properties of a PCD tool, which has steep flanks and different reflection properties.

Automotive industry: Leak testing of valves

Also for valves, both dimensional accuracy and surface quality effect the required tightness. Here, roundness and roughness on the contact surfaces must be precisely verified, because even minimal roundness deviations in the single-digit µm range can have a negative effect on the tightness. "With Bruker Alicona, we can easily measure geometric features that are difficult to access with other methods," says Yu Quin. "Even the steep flanks and small geometries of the valve seats are measurable, unlike with other measuring devices. Form and position tolerances can also be easily verified."

Aviation: Break edge and cooling hole geometry

One of the most frequent requests from the aviation industry is break edge measurement of turbine engine components. The machined or rounded edges must lie within narrowly defined tolerances, and the geometries to be measured are often only a few tenths of a millimeter. Focus- Variation is suitable here from several points of view. It enables the measurement of very shiny areas with steep flanks and captures the geometry in high resolution, allowing even the smallest form deviations to be measured precisely. "In addition to break edge measurement, we are receiving more and more enquiries for measuring the cooling hole geometry," says Yu Quin. In her opinion, the geometric verification of cooling holes is a leading discipline in metrology. "In addition to a technology that can measure the geometry and position of the cooling holes in relation to a reference system, this application requires a high demand for automation. We know measuring tasks where up to 500 different cooling holes at different positions should be verified". The center sees Bruker Alicona as a suitable supplier in this area as well, and an expansion of the existing measuring systems with appropriate solutions is discussed. The optical micro coordinate measuring machine µCMM suitable for this measurement task will soon be available at the Metrology Center of SPSM.

Automation is fundamental for production monitoring with real-time data

Yu Quin sees automation, networked manufacturing and measurement data analysis as the most significant measurement technology trends for the future. "The decisive advantages in the competition for efficient manufacturing technologies of complex parts is automation and networking," she says, "This is how real-time process data for adaptive production planning and manufacturing optimization can be obtained.” Bruker Alicona is a valuable partner for this project, as they provide tried and tested automation solutions including networking with existing production and IT systems. So, future projects are in the pipeline. One can say that these are promising opportunities for customers and project partners of the Shanghai Manufacturing Platform for Smart Manufacturing.