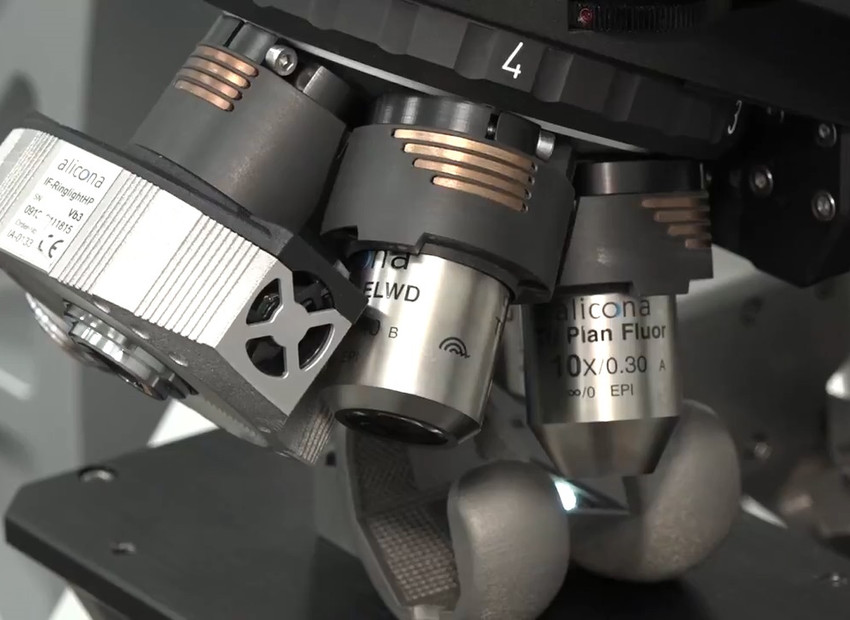

The development of new manufacturing techniques and technologies has always been the mission of AMRC, the University of Sheffield Advanced Manufacturing Research Centre based in the UK. It "helps manufacturers of any size to become more competitive by introducing advanced techniques, technologies and processes”, AMRC states. To achieve this, metrology is one of the key activities at AMRC. Skilled in many areas of metrology, the team supports the research groups by qualifying novel parts and processes to make sure that they meet physical requirements and industry standards. In the field of optical metrology, Bruker Alicona´s high resolution form and roughness measurement systems deliver the greatest benefits than with any other system AMRC experts are aware of. It is not without reason that the globally well-known research center recently has acquired its fourth Alicona measuring system.

"We fully automate a lot of the testing”

"We are developing an automated machining test cell to test new materials such as cutting tools, coolants and overall machining technologies. Combined with a robot, an Bruker Alicona optical measurement sensor is part of the cell, allowing us to automate all kinds of measurements.” Thomas McCleay, Head of Research, is enthusiastic about the increased efficiency and higher output he gets by utilizing automated measurements in his test series. "We fully automate a lot of the testing. Automated measurements allow us to significantly increase the number of tests we can do in a single day, so we can explore a lot more technologies in shorter time.” The results obtained from the initial test measurements feed into more feature-based trials, which again lead to the next level of technology readiness and thus to production suitability.

Accessibility to industry for full test automation

Today, measurements in research activities at the AMRC are mainly carried out to explore a broad range of options for tooling and all kinds of cutting materials. However, since the Bruker Alicona measurement systems can be utilized to measure nearly any kind of solid components including miniaturized and complex geometries, this test cell is planned to become accessible to all industry partners. "The automated test cell will be rolled out to industry, so our industry partners will have the chance to gain access to full test automation as well. The uptake of this way of developing is also an answer to a growing market pull, and the Bruker Alicona measurement technology is the best that we have available. The partnership with Bruker Alicona is key to make sure we can achieve this type of automation and integration. Hence, with Bruker Alicona we see the route to market,” McCleay says.

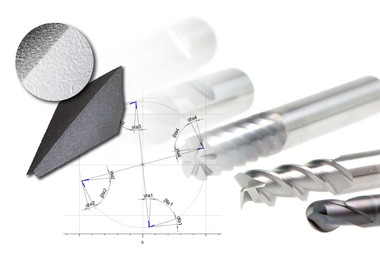

Tool wear assessment in composite machining

One of various specific aspects in the development of new manufacturing techniques is tool wear assessment. Oliver Hayes, Composite Development Engineer, uses Bruker Alicona to see how the tool is wearing as it progresses through its life. "In composite machining, we generally see that the type of wear experienced by the tool is mainly flank wear. Because of that we need Bruker Alicona as I don´t know any other system that allows us to measure the steep flanks of e.g. PCD tools,” he explains. In his daily work, Hayes also needs to measure surface roughness. For him it is of vital importance to measure roughness areal based instead of measuring only a profile of the surface. "In the context of carbon fibre, the Ra value depends on the angle at which you measure it. Because of that, we prefer to use the areal surface roughness value Sa which we easily get with Bruker Alicona.” In terms of efficiency and ease of use, Hayes benefits from measurement automation as well. "You can set the system going, have it move to several positions and take surface roughness measurements of several different samples. This is something I really like, and you cannot do this with a tactile CMM”, he concludes.

Advantages of optical Focus-Variation technology over a traditional CMM machine

"The Bruker Alicona system is ideally suited to small features including small radii and diameters of a hole which are challenging if not impossible with a CMM”, CMM Technical Lead Adam Wiles continues when speaking of the advantages of optical measurement over tactile scanning. An additive manufactured component illustrates the benefits. "We have here an additive manufactured knee joint with a lattice structure on the back surface. This surface is impossible to measure with our CMM, however, it takes only a few seconds to achieve a measurement with Bruker Alicona. We measure distances, node distances, string diameters, also surface roughness.” For Wiles, the combination of roughness and geometrical measurements is unique, especially as complex components regardless of industry usually require both for meaningful quality assurance, the measurement of form and roughness. While conventional techniques are capable to do either one or the other, Bruker Alicona combines form and roughness measurement in only one high-resolution optical measuring device. "You can do surface roughness on a CMM, but it requires a real specialist kit,” Wiles emphasizes.

Understanding tool mechanisms to improve manufacturing processes

AMRC is particularly active in the fields of aerospace, automotive and transport, energy, food & drink, healthcare and infrastructure. Metrology is relevant to achieve technology readiness level targets independently of industry. This is the core competence of Ian Cook, Technical Lead for Machinability. He and his team are confronted with relatively low technology readiness levels, and Bruker Alicona helps to gain detailed information about new tool designs and corresponding types of tool mechanisms that are typically seen with new materials. A feedback loop between application teams and further targeted platform groups supports the progress of technology readiness with the aim to improve the overall manufacturing progress. Cook agrees that Bruker Alicona significantly contributes to the world leading research activities of AMRC: "With Bruker Alicona, we maintain our high quality.”