Automated tool wear measurement in machining processes

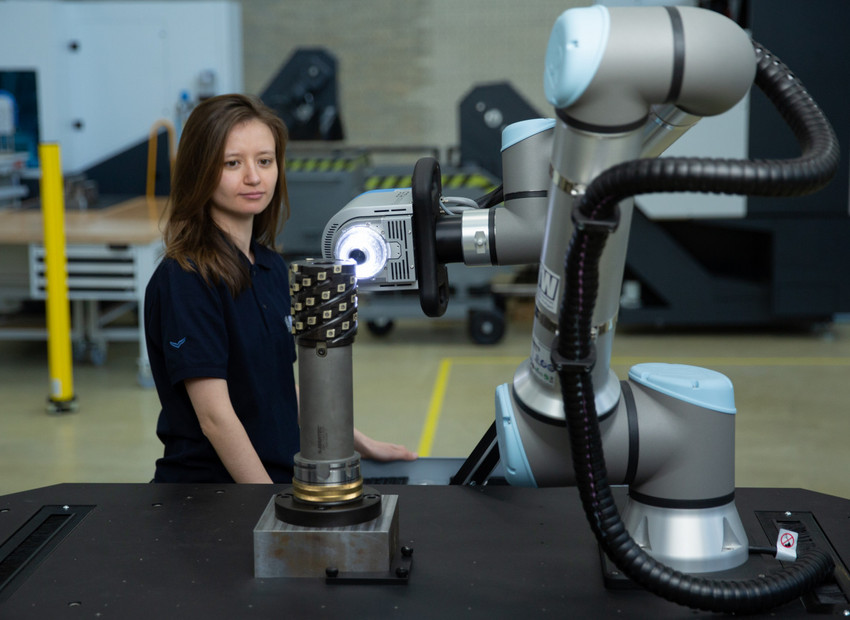

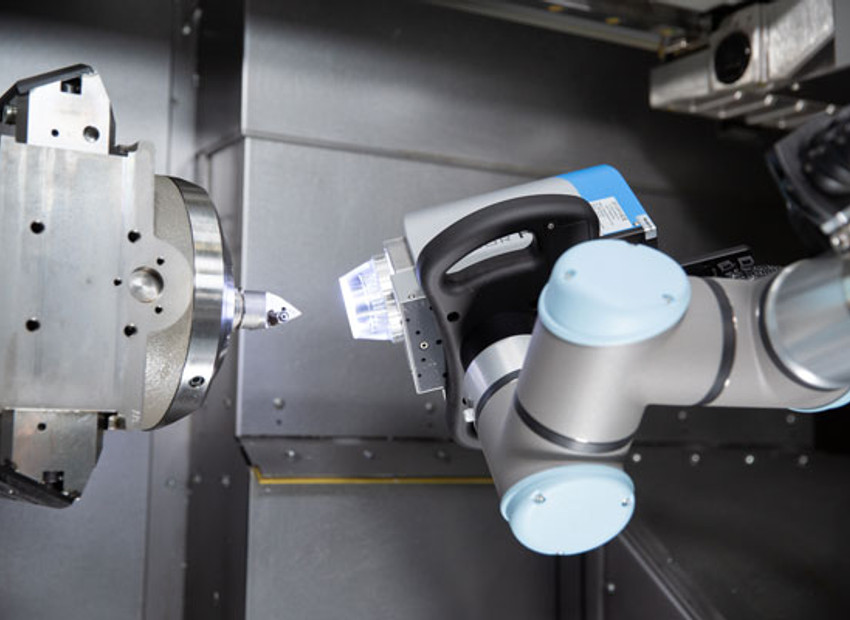

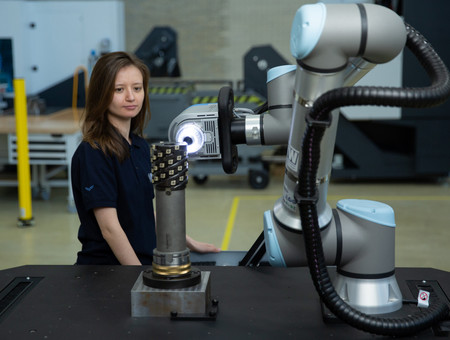

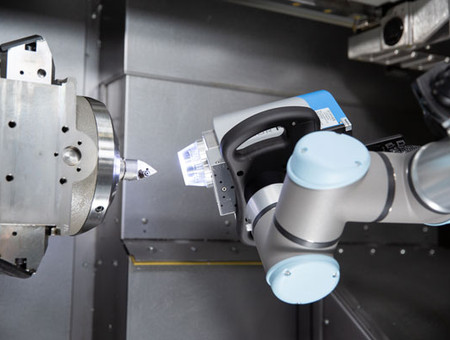

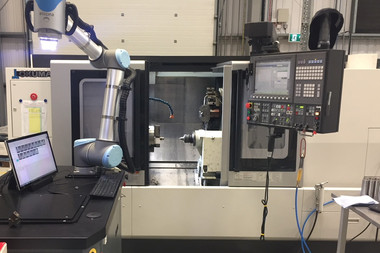

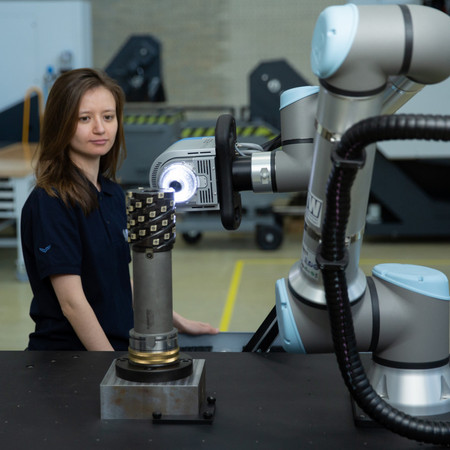

At the Institute for Machine Tools (IfW) at the University of Stuttgart, a Compact Cobot relieves employees of the task of measuring tool wear. The system consists of a UR10e from Universal Robots and an optical 3D measuring sensor from Bruker Alicona. It enables measurements directly in the machine tool, eliminating the need to clamp and unclamp the tool. Measurements have thus become faster and more efficient.

Sarah Eschelbacher

Group Manager Process Monitoring & Control, IfW Stuttgart

The operation of the Cobot is very intuitive. Many colleagues and students are now working with it. Once you have programmed the measuring points and the sequence, the Cobot takes over the measuring process all by itself.

READ THE ENTIRE SUCCESS STORY

Automated tool wear measurement in machining processes

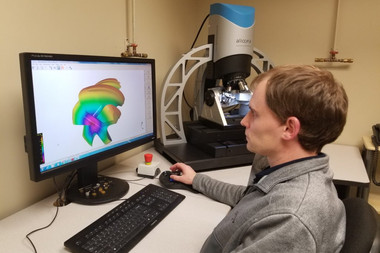

More than 30 scientific employees conduct their research at the IfW in the following areas: design and optimization of machine tools, cutting manufacturing technologies and additive manufacturing. The IfW team provides important insights into Industry 4.0, including studies about the use of tools in machining processes and the associated tool wear, but also about the effects on the machined workpieces.

Tool wear plays a crucial role in machining processes. It affects tool costs for companies and has a direct impact on surfaces. In the past, researchers had to unclamp the tool from the machine, transport it to the measuring device and clamp it there, which was a time-consuming task. This challenge, combined with measurement inaccuracies during reclamping operations, let the IfW team implement a new, automated approach.

How IfW succeeds with Bruker Alicona solution

Cobot series

Optical measuring sensor & collaborative robot

- Verification of surface quality & dimensional accuracy of small features on large components in existing production environments

- Easy teach-in of measurement series: no prior knowledge of metrology necessary

- High mobility & flexibility: Measurement of components directly in the machine tool