‘Supermaterials’ is a term that includes manufactured synthetic diamond as well as cubic boron nitride (CBN), tungsten carbide and silicon cemented diamond. Element Six, a member of the De Beers Group of Companies, produces specialised, innovative high performance products from supermaterials, including materials for machining and grinding metals in automotive manufacturing, cutters for oil and gas drilling and optical windows for high power laser systems.

Optical 3D measurement to test cutting and grinding applications

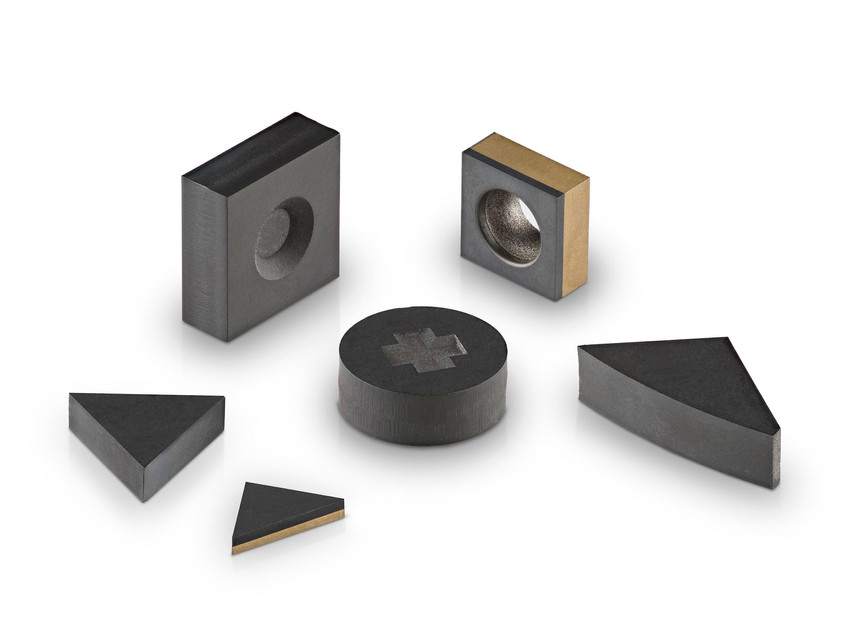

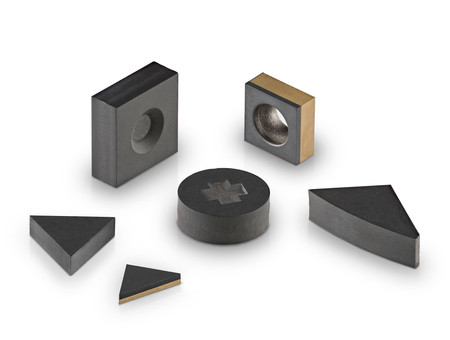

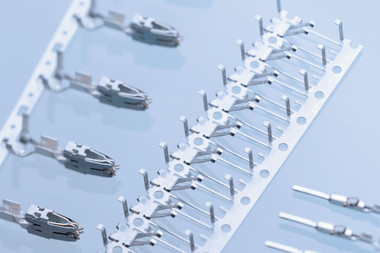

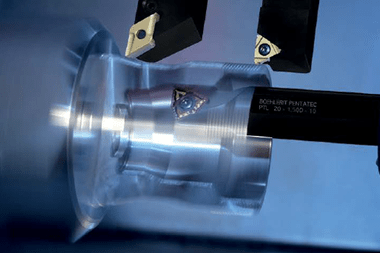

At their Global Innovation Centre (GIC) in Harwell, UK, Element Six develops synthetic diamond supermaterials for a wide range of industrial applications. Within cutting and grinding applications, this means developing new polycrystalline cubic boron nitride (PCBN), polycrystalline diamond (PCD) and diamond or CBN grit for precision metal cutting and grinding operations. In order to fully test these new materials in industry relevant applications, Element Six produce ISO cutting inserts to be used in metal cutting tests on lathes and milling machines, where in-process forces, tool wear and workpiece surface quality are measured and analysed.

"We needed a system to quickly and accurately measure tool geometries and wear”

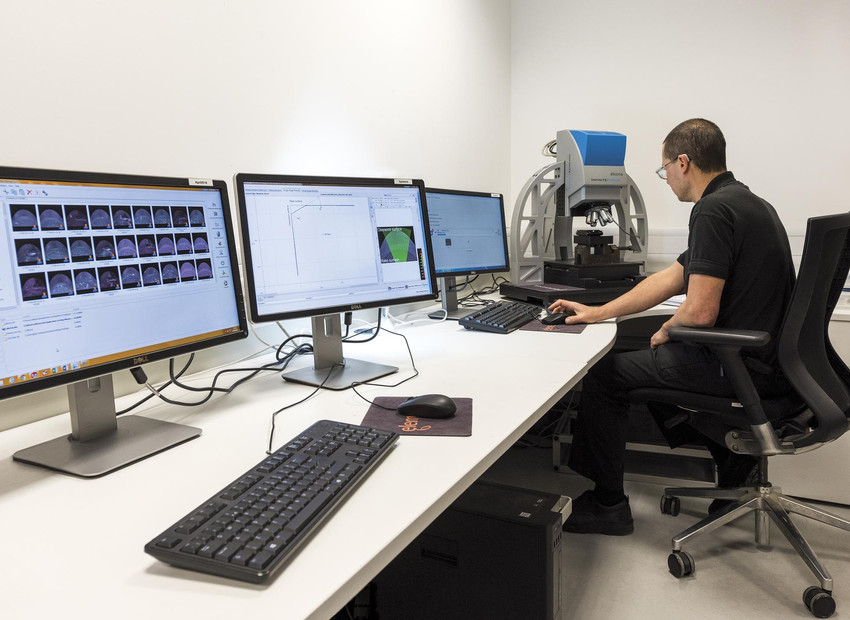

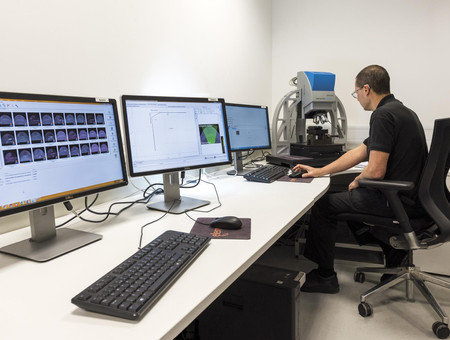

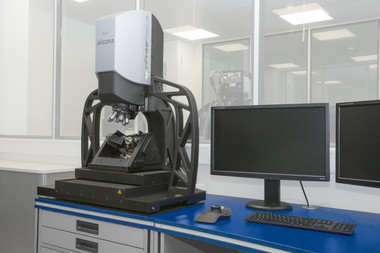

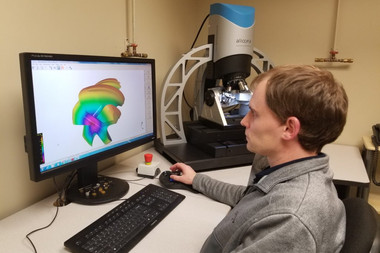

Fast feedback to the technical teams developing the tool materials is key to rapid innovation. With InfiniteFocus, Element Six has a single measurement system that accelerates this development feedback and provides the flexibility for use across its varied application testing program.Matthew Goulbourn-Lay, Senior Advanced Manufacturing Research Engineer at Element Six explains: "We have been using Bruker Alicona for more than a decade now. Initially, we needed a system that could quickly and accurately measure tool geometries and wear scars. Before, we would have to take many different measurements using various systems and equipment. With Bruker Alicona we have a single system from which all our measurements and analysis can be taken.”

Optimizing the edge preparation in µm and sub-µm range

In the manufacture of ISO cutting inserts for testing purposes, Goulbourn-Lay’s team use the Bruker Alicona systems to speed up their quality control processes. A poor edge preparation can mean edge defects, micro-breakages, burrs, poor surface finishes leading to non-optimal cutting performance. The verification of geometry and surface finish is therefore indispensable. Element Six uses the optical 3D measurement system to measure parameters like chamfer angle, hone radius dimension and chamfer width to within 3 microns. Due to its special technology, InfiniteFocus is able to accurately measure the most complex cutting tool geometries with even very steep surface slopes.

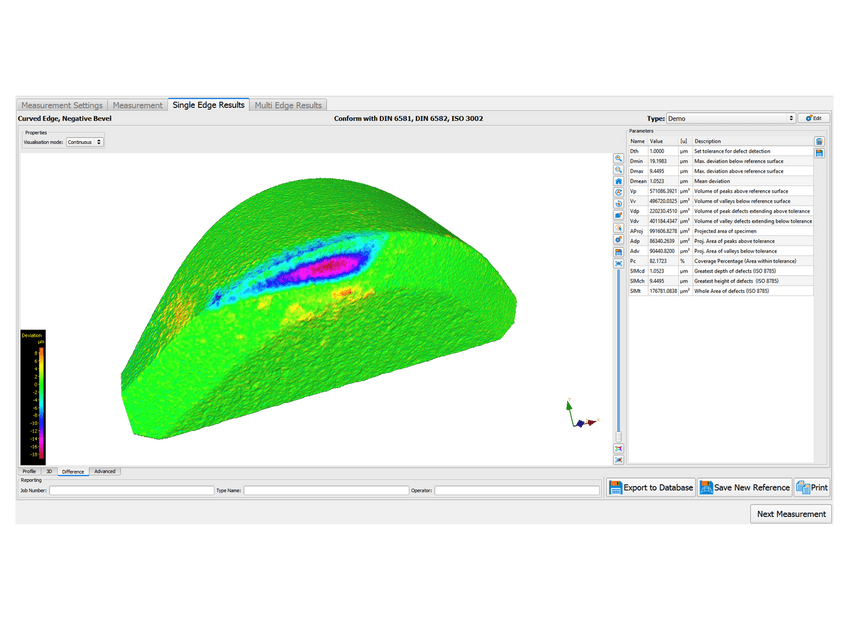

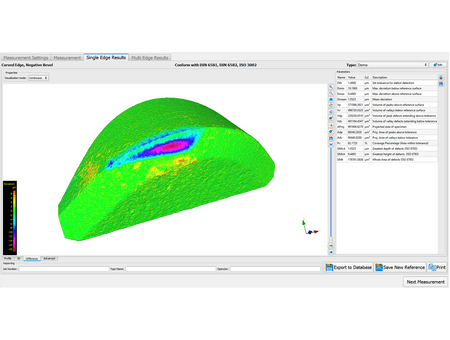

Evaluating the total volume of worn and accumulated material

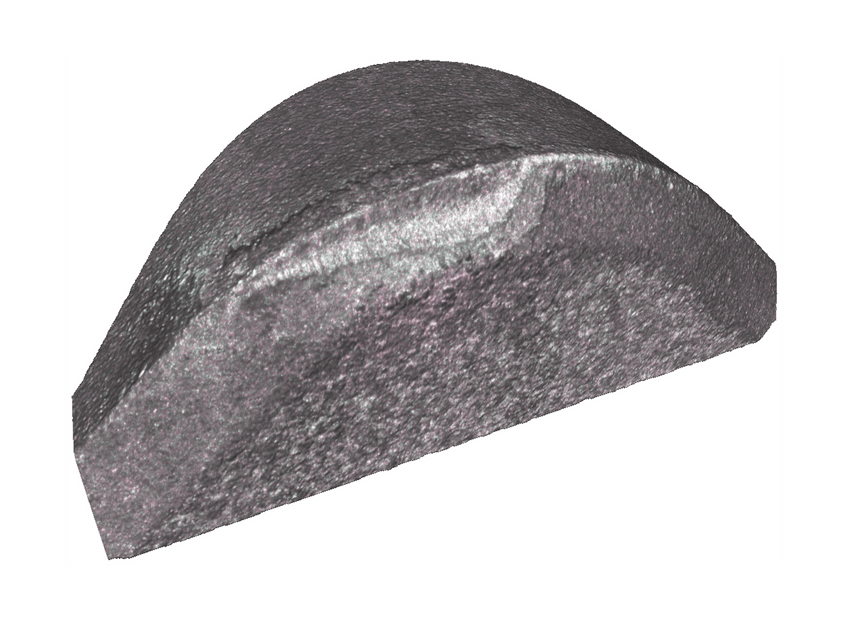

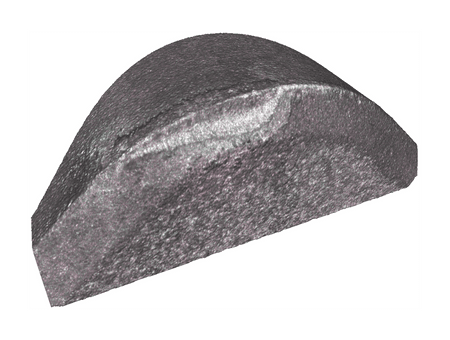

In a second stage, Element Six compares the three-dimensional structure of the tools before and after their usage to determine important parameters, such as the total volume of worn and accumulated material. Measured parameters include crater depth and volume, the maximum and mean defect across the clearance surface, flank wear as well as the notch wear. This gives information about the contact between the edge and the workpiece during the cutting process. Matthew Goulbourn-Lay explains: "In order to test how each new development material is wearing, we compare the wear scars of different materials. The various measurements and visualization taken allow us to build a better picture of how a specific tool material wears over time. This has led to numerous material developments in both PCBN and PC.

Fast measurement results for quick feedback to the production route

Due to the short measurement time, feedback to the production route can be provided quickly and machine parameters adapted accordingly. Also, InfiniteFocus provides true colour information for each measurement position, which is perfectly registered to the height data. Chipping in the micro- and submicrometer range is visualized with colour coding, which has helped Element Six to show chemical and abrasive wear of the tool. Matthew Goulbourn-Lay points out: "We have also used surface mapping across large diamond discs which have been worn in their specific application. Understanding the depth and map of the wear has been incredibly useful.”

Flexibility and wide range of possible measurements

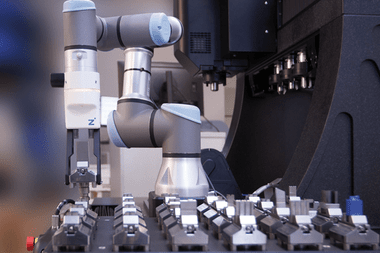

Goulbourn-Lay and his team were impressed with the flexibility of the measurement system and range of different measurement options available, providing the ideal solution for the R&D environment. After using the InfiniteFocus G4 system for many years and having upgraded it, the Element Six decided in 2016 to invest in a second Bruker Alicona solution, the successor InfiniteFocus G5 system. "We wanted the same software that our people knew and that was easy to handle. Repeatability is important for our quality control process and we appreciate the systems’ flexibility in use and abilities”, Golbourn-Lay concludes.