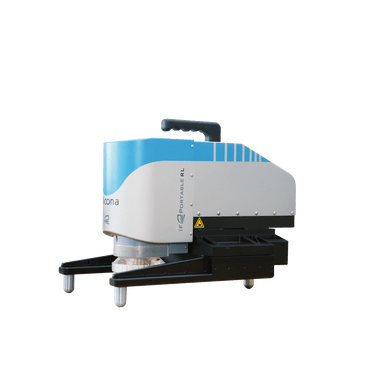

Automatic optical measurement without any operator influence

Automation is more than the automatic measurement of surface roughness and form parameters. Automation means simple interaction between administrator and machine operator, intuitive order management, high measuring accuracy as well as simple communication and networking with existing production systems including the connection to an ERP and QM system. The following is an overview of the automation options available. The range includes "simple" automated measurement up to the realization of Smart Manufacturing.

The AutomationManager software offers a variety of automation options:

Automated optical measurement with the AutomationManager software

The AutomationManager software platform enables the automated and user-independent surface measurement and evaluation of micro-precision components or micro-structured surface details on large components.

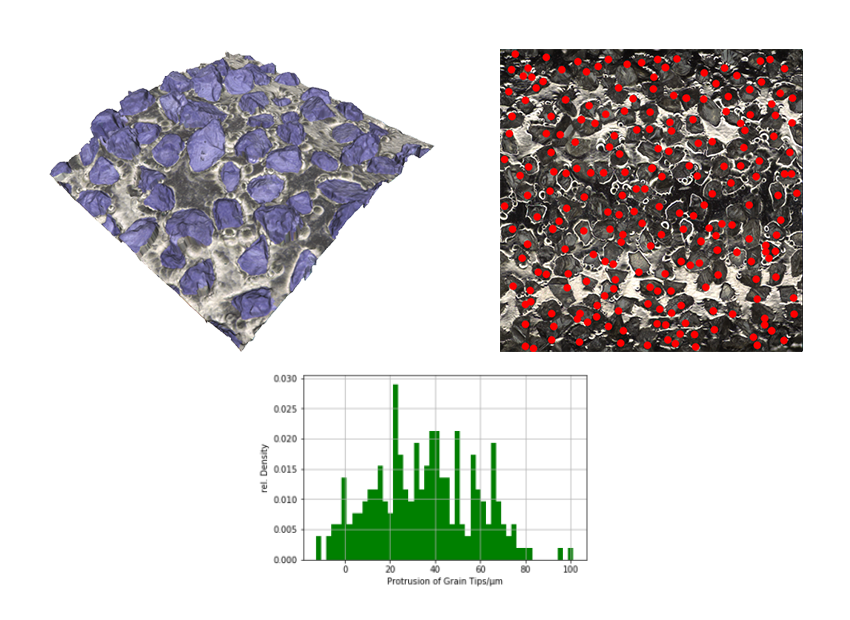

The process is based on the interaction between an administrator, who defines the measurement program, and operators in the production area. The operator starts pre-programmed measurements at the touch of a button, the selection of the components to be measured is done using a drop-down menu or barcode scanner. The measurement and evaluation of surface roughness and/or form parameters proceeds automatically, the worker has no influence on the measurement result. At the end an O.K./not O.K. report is provided. Modular expansion options in the areas of defect detection and surface treatment by grinding, shot peening and laser complete the evaluation methods.

Automated roughness measurement

Automated form/shape measurement

CAD CAM Connection

Connection to ERP and QM systems

Machine to Machine Communication

Modular expansion options