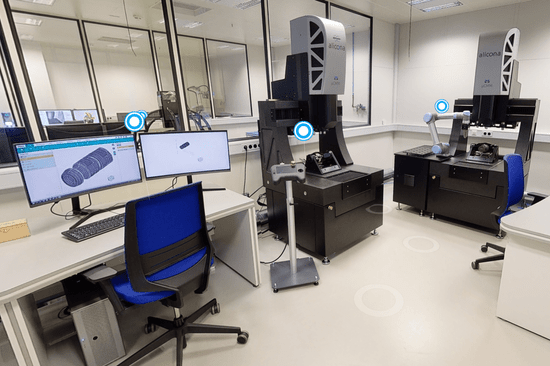

Non-contact and highly accurate measurement of critical turbine engine components

Turbine engines are highly specialized aircraft components that must meet enormous safety criteria. They are precision components with complex geometries and tolerances in the sometimes single-digit μm range. Functional component features such as micro bores for cooling turbine blades or defined broken edges on highly stressed components contribute both to increased efficiency and to the safe operation of these high-performance systems. One way to meet the new metrological requirements is the use of high-resolution, optical 3D metrology.

Learn more about...

- Applications of Focus-Variation in quality assurance: e.g.

- Break edge measurement

- Dimensional measurement of leading & trailing edge

- Defect measurement

- Automatic measurement of cooling holes

- Monitoring coating processes

- Possibilities of Artificial Intelligence (shot peening processes, evaluation of laser treatment)

- Cobots: automation of optical sensors with Focus-Variation

Optical measurement of critical turbine engine components

Share this article