Automated production cell with optical metrology

KLEINER Stanztechnik combines machine tools, measuring technology and robotics in a new production cell. It aims at autonomous, fully automatic production of tool components including measuring protocol. Bruker Alicona is not only a selected measurement technology partner because of its automation capabilities.

Christian Hamann

Business Unit Manager Tool Technology

With Bruker Alicona we are already able to automatically start and execute the measuring process in our production process. We are currently working on enabling networking with other machines so that machine parameters are automatically and continuously adjusted based on the measurement results.

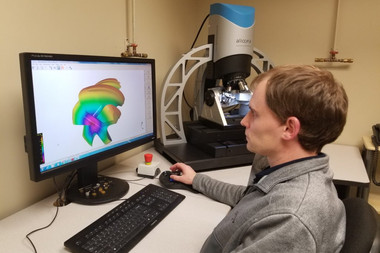

Bruker Alicona Measurement System at Kleiner 2.0 - see in this Video how Kleiner integrates the optical CMM with a high precision rotation unit directly in the manufacturing cell.

READ THE ENTIRE SUCCESS STORY

Optical 3D measurement combined with tooling, molding and industrial robotic technologies

Christian Hamann, Business Unit Manager Tool Technology at KLEINER Stanztechnik, remains modest: "I can’t just say whether our new production cell makes us stand-alone worldwide. But our customers confirm that they have not yet seen a comparable production cell with integrated measurement technology at this high degree of automation.” The German stamping technology company has been proud to combine expertise in the field of precision stamped parts and high-performance stamping tools with new technologies since its foundation, thus meeting increasing customer demands from various industries.

With its new production cell, combining technologies from tool and mold making, metrology and industrial robotics, KLEINER once again proves its innovative strength. For Christian Hamann, the commissioning is a milestone: "At the moment, man and individual components of the cell are still interacting with each other. The production cell in its final state will enable completely self-sufficient production with a fully automatic process. We hand over a raw part to the cell, and at the end we receive a completely manufactured tool including measuring report without any further intervention.”

How Kleiner succeeds with Bruker Alicona solution

InfiniteFocus

Dimensional accuracy & surface finish measurement

- Accurate, fast and universal optical 3D measuring instrument for tolerances in the µm and sub-µm range

- Components are measured area-based and with high resolution independent of size, material, geometry, weight and surface finish

- A number of proven and new features combine the functionalities of a roughness measuring system (Ra, Rq, Rz/Sa, Sq, Sz) with the characteristics of a coordinate measuring machine