Des relations d'affaires qui enrichissent les deux partenaires

Visiting our customers is always like visiting friends. In November, Claudia Ullrich, Marketing Expert and Florian Schwimmer, Marketing & Sales Director visited the dental company Zfx in picturesque Gargazon. The reason for the meeting was to write a nice success story about the use of the Bruker Alicona µCMM . The result was so much more.

Werner Weithaler and Lukas Breitenberger

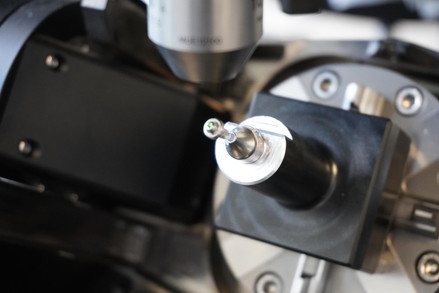

During a generous tour of the Zfx premises and production site, we were not only able to see how and what is being worked on. Lukas Breitenberger, General Manager of Zfx, also gave us an insight into the world of medical technology. We learned how the Medical Device Regulation (MDR), which has been in force since 2017, has changed quality management. Not that Zfx had any catching up to do in this area. But the bureaucratic effort has multiplied. As Breitenberger himself explained, the hurdles for launching new products on the market have become extremely high. But changes to the production process are now also difficult to implement and require a great deal of time and money. In the past, as now, the connecting pieces between the implant and crown (so-called abutments or titanium bases), the implants themselves and screws were measured. As some of these are extremely small components with lengths of 10 mm and diameters of less than 2 mm, the tolerances are correspondingly tight. They are around 2 µm. The MDR has not changed this.

Incidentally, Zfx is part of the US group ZimVie, which specializes in dental and spinal medicine. Together, parent company ZimVie and subsidiary Zfx are strong competence partners in the field of dentistry. Their areas of application range from implant technology to the latest dental prosthesis materials and state-of-the-art production processes. Zfx has two company headquarters: in Dachau, Germany and in Gargazon, Italy. Quality control takes place exclusively at the Gargazon site and focuses on incoming products as well as prototyping.

We learned so much during our stay at Zfx that we really had to think about what we actually wanted to talk about, namely the use of the µCMM . Zfx put an InfiniteFocus G5 from Bruker Alicona into operation five years ago. Werner Weithaler, Sr. Engineering Manager Zfx, described the decision situation for the µCMM as follows: "The InfiniteFocus G5 has met our quality assurance requirements from the very beginning. We can neither complain about defects nor about inadequate measurements. And because we were already so satisfied with the G5, it was clear that Bruker Alicona would be our first point of contact again." It must be said, however, that the CMM delivers greater accuracy in the room and can significantly reduce the duration of the extensive measurement plan thanks to local optical probing. Incidentally, the G5 is still in use.

And then there is one more thing, namely automation. A few months after the µCMM was commissioned, it was given an update in terms of automation and capacity utilization by entrusting a pick and place with loading. This allows the measuring device to run 24/7, without an employee having to be on site. The workflow is therefore never interrupted.

Of course, we were also really impressed by the use of the µCMM at Zfx. But behind-the-scenes customer insights are particularly valuable. You can read the whole success story here. Below you find the press release for download.