La metrologia ottica 3D per gli stampi di precisione è una cosa importante?

Even in the production of stamping, punching and bending dies you are not immune to trends. Of course, you are right to ask yourself which developments offer real added value and which are just a new toy for employees. And which category do the optical 3D measuring devices that the competition has already bought fit into? You can easily find the answers in your own company.

Your company is on a solid footing. Production is running like clockwork. Actually - let's be honest - a company of your size doesn't need measuring systems that check down to the last micrometer. The really big players might, but they are a different caliber. But somehow the question keeps coming up - from production, from quality assurance employees and so on. And this is exactly where you have the biggest competitive advantage. Because many medium-sized companies think they can do without it because they are not in the top league. How much do you think your business will stand out if you use Bruker Alicona measuring devices to increase both quality and productivity?

It is a more than legitimate question whether a measuring device in the price ranges from InfiniteFocus to µCMM will pay off. With your input, we can certainly answer this question together. How much do production errors caused by inaccuracies during punching, bending, stamping or deep drawing cost you? Once? Per year? Over the entire life cycle of the machines? Very high quantities come off the production line. And even small defects in precision components can render entire batches unusable.

After doing the math, you may come to the conclusion that a measuring device in the price range of the Bruker Alicona systems is actually not worthwhile. The costs for faulty productions are not that high. But what if you lose an order due to faulty production? A big one? What if the customer realizes that the competition can deliver much faster and with greater precision thanks to the use of optical 3D measuring devices? The automation of the measurement leads to an increase in productivity - higher quantities, shorter production times. In other words, the competition delivers better quality in less time.

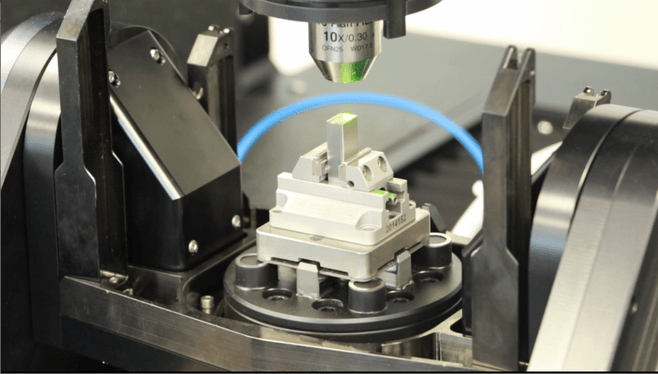

Is your company making do with the current systems? If you are unsure whether Bruker Alicona could help increase your productivity, here is a list of the most important applications for micro-precision manufacturing:

Incidentally, this list is only an excerpt. Even if you cannot find your area of application one hundred percent, please feel free to contact us. The range of applications for Bruker Alicona measuring devices is constantly growing, and fully automated solutions are our daily bread.

Of course, the decision for or against a precision measuring system is not an ad hoc decision and, as mentioned at the beginning, the answers can be found in your company. Nobody knows it as well as you do and only you can decide whether you want to take it to the next level. We would be happy to advise you on all the possibilities that precision measurement technology can offer your company.

Not sure, how optical 3D metrology can improve your production? Find here our video "5 steps to improve competitive advantages of your precision dies".