Are you ready for Control Show 2023?

We would like to welcome you to the 35th Control, the world's leading trade fair for quality assurance, from May 9 - 12, 2023.

Learn from us how you can solve your complex metrology requirements smarter, faster and more accurately.

With Bruker Alicona's innovations you will achieve the Max Quality in Production.

We look forward to seeing you!

Meet us at: Hall 5 | Booth 5401

Fraunhofer exhibition: Hall 7, booth 7401

The following highlights await you at our booth:

The new standard of probing is optical.

The stylus is out of style. Bruker Alicona enables faster, optical, non-contact probing of contours on complex parts without the pain of stylus influences like force compensations or surface smoothing, complex articulated setups, changing of styluses, slow scan speeds and many more. At Control you can learn how to optically measure and evaluate dimensions within seconds with only one sensor and the new technology of Focus Probing.

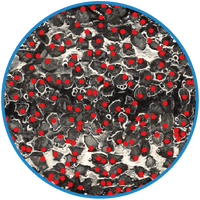

What's new in surface texture? Unprecedented speed and empowerment by AI.

Measure surface roughness compliant to the new ISO 25178 standard faster than any other optical 3D measurement device. In addition to roughness measurements our new AI-powered software plugins enable you to classify any surface automatically and reproducibly. See both developments in the surface texture live session.

From buzzword to actual added value: How to use Digital Twins to increase manufacturing intelligence.

Learn about the 3 cornerstones of Digital Twins at our booth: Measurement planning with CAD data, simulation and real-time quality data for your manufacturing process. See how you can start the future now and implement these principles today.

Quality control with a new level of smart. Complex measurement made easy.

Bruker Aliconas MetMax Software fully embraces automation of measurement routines. With the example of a high precision stamping die find out how easy complex metrology tasks, such as 'profile of a surface', can be handled when the metrology software acts as your smart assistant every step of the way.

You can´t be on site but you are curious what´s behind these innovations?

Join our LinkedIn live sessions!

Experience our measuring solutions for your shop floor live on site

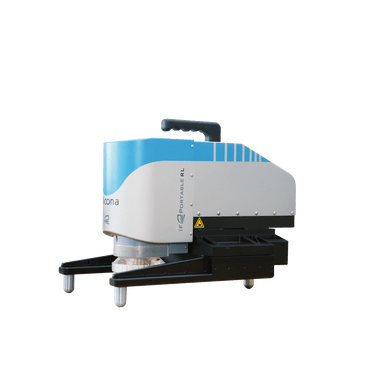

µCMM

The first purely optical micro-coordinate measuring machine on the market can measure extremely tight tolerances in high accuracy, combining advantages from both tactile coordinate measuring technology and optical surface measuring technology. Dimension, position, shape and roughness of your components are measured with only one optical sensor!

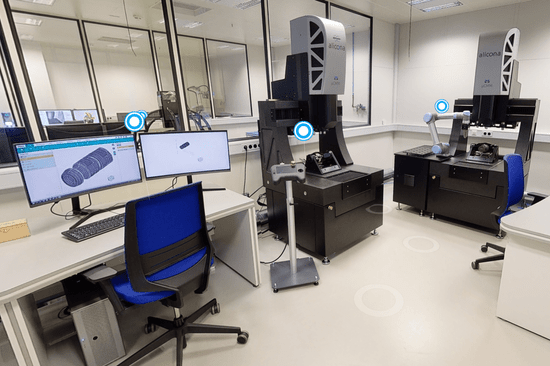

The new

InfiniteFocus G6

InfiniteFocusG6 is an accurate, fast and universal optical 3D measuring instrument for tolerances in the µm and sub-µm range. Components are measured area-based and with high resolution independent of size, material, geometry, weight and surface finish. A number of proven and new features combine the functionalities of a roughness measuring system (Ra, Rq, Rz/Sa, Sq, Sz) with the characteristics of a coordinate measuring machine.

dieSonne-128-399x266.jpg)

Learn more about our optical 3D measuring solutions for the shop floor

What is Focus Probing?

The measurement principle of the new method Focus Probing is very similar to the Vertical Focus Probing technology with the difference, that no vertical scanning is involved, but that 3D information is obtained from the sensor data at a single position. As with Vertical Focus Probing, Focus Probing also allows the measurement of contours at vertical walls, with the extension, that also multiple 3D contours can be measured within one field of view at once.

Intelligent measurement planning with the operator software MetMaX

The MetMaX software sets new standards in usability. Users specify measurements already on the CAD model of a component. A digital twin combined with a virtual measurement simulation enables safe operation of the measuring instrument.

dieSonne-145-500x333.jpg)

More optical 3D measuring systems at Control 2023

Visit us at Control 2023

May 9 - 12, 2023 | Stuttgart, Germany

Hall 5, booth 5401

Fraunhofer exhibition: Hall 7, booth 7401

3 reasons why you should visit us

Bring your component &

we measure together on site.

Find your ideal measurement solution.

Get to know us in person.

dieSonne-154-2000x980.jpg)