The Coordinate Measuring Machine for High-Precision Manufacturing

You are dealing with

- Increasing quality demands

- Time-consuming measurement routines

- Challenging materials and geometries

- A shortage of metrology specialists

…then the coordinate measuring machine µCMM from Bruker Alicona is exactly what you need.

Measure dimensions, position, form, and roughness – with only one optical sensor – fully automated and optimized for the shop floor.

Let us show you how the CMM machine can be integrated into your workflow.

Fast, accurate, reliable, and tailored to your application.

Optical coordinate measuring machine µCMM

What is an optical coordinate measuring machine (CMM)?

An optical CMM is a non-contact coordinate measuring device that delivers highly accurate 3D data of your components – fast, reliably, and directly in the production environment. It is used to measure extremely tight tolerances in high accuracy. Users combine advantages from tactile coordinate measuring technology and optical surface metrology.

- NO stylus changes

- NO surface damage

- NO compromise on accuracy

What is optical dimensional metrology?

Optical dimensional metrology delivers fast, non-contact, and highly precise 3D measurements of size, shape, and geometry. Ideal for both the shop floor and the lab, it ensures reliable, repeatable, and traceable results in real time. By harnessing advanced optical technology, it boosts quality control, streamlines workflows, and drives accuracy across a wide range of industries.

Why manufacturers like you choose the µCMM

The coordinate measuring machine offers:

- Highest accuracy – even on complex geometries with tight tolerances

- Non-contact measurement – ideal for delicate or high-value materials

- Automated at the push of a button – increase throughput and reduce operator error

- Simple operation – No metrology expertise required, thanks to the smart metrology software MetMaX

- All-in-one sensor – measure dimension, position, form, and roughness with a single sensor

The µCMM is not only a measuring device but your partner in quality control. Trust in Bruker Alicona’s proven technology and sustainably optimize your manufacturing processes.

The µCMM solves real challenges in production

Pressed for time but need high precision?

Fully automated measurements save time and reduce human error.

Dealing with safety-critical parts?

Get reliable, repeatable results for full traceability.

Complex shapes that can’t be touched?

Optical 3D metrology measures even fine details – without contact.

Mixed-material components?

µCMM handles everything from PCD and ceramics to CFRP and silicon.

One Solution – Trusted Across Various Industries

The coordinate measuring device µCMM is versatile and supports various industries in quality assurance and process optimization. Here are some examples:

- Automotive: Precise measurement of engine components, transmissions, and body parts to ensure the highest quality standards.

- Aerospace: Analysis and measurement of turbine blades, aircraft parts, and other safety-critical components.

- Electronics: Inspection of PCBs, microelectronics components, and other highly sensitive electronic parts.

- Medical Technology: Accurate measurement of implants, prosthetics, and surgical instruments to meet strict medical standards.

Optical measurement of precision dies (punches, stamping and bending tools) with the optical cmm machine

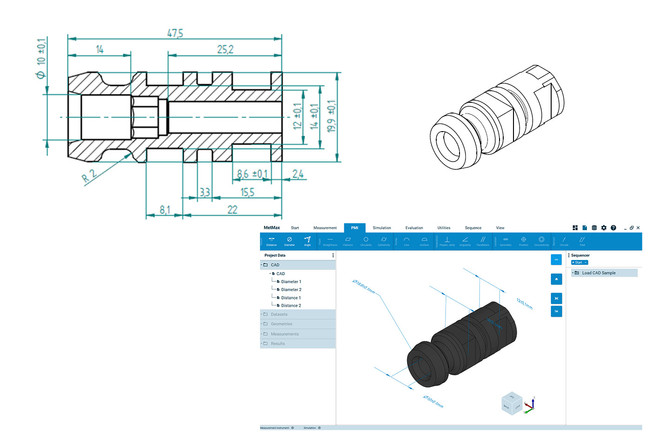

Smart, automated measurement with MetMaX

With the intelligent MetMaX software, quality control becomes a seamless part of your production:

- Upload CAD file

- Select GD&T or PMI features

- Start the scan – the software handles alignment and analysis

✔ Repeatable. Traceable. Intuitive – no special knowledge required.

Boost your efficiency, save time, and improve your production precision with MetMaX.

Download the product brochure

Want the full product details and tech specs?

Get your free product brochure now and discover how the µCMM transforms your process.

dieSonne(6)-2000x857.png)

dieSonne(6)-2000x3000.png)

dieSonne(6)-2000x2000.png)