Accurate and easy measurement of wear

Do you already measure the wear of your cutting tools, but you are repeatedly confronted with high measurement uncertainties?

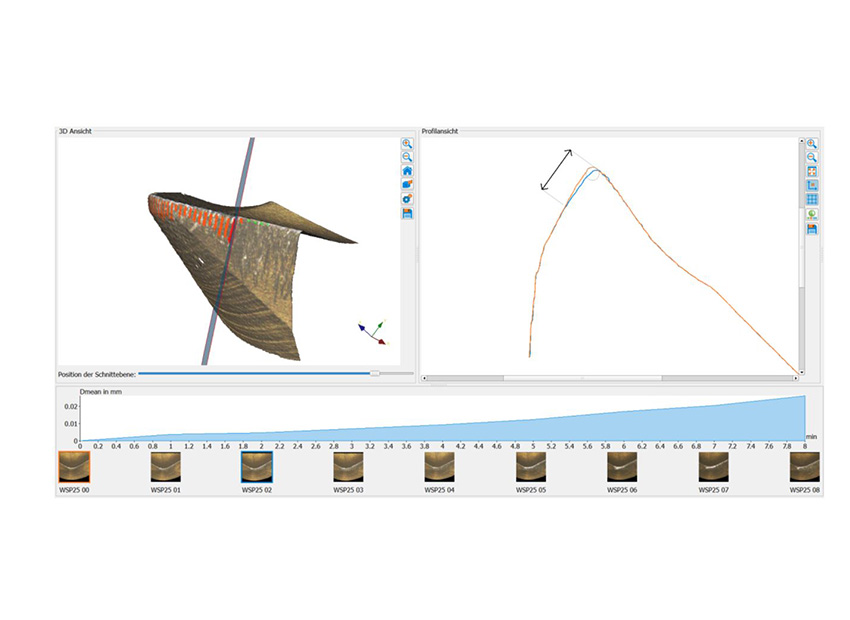

The Bruker Alicona Wear Measurement enables you to visualize and quantitatively assess wear on cutting edges based on high-resolution real 3D measurement data. In this process, wear is measured and analyzed over a certain period of time. The measurements are performed over the tool's lifetime repeatedly, either directly in the machine or separately.

The software is an extension of the Bruker Alicona measuring systems for optical cutting edge measurement. Users automatically measure differential parameters and wear parameters according to ISO 8688 (Tool Life Testing in Milling), such as flank wear.

The WearMeasurementModule enables:

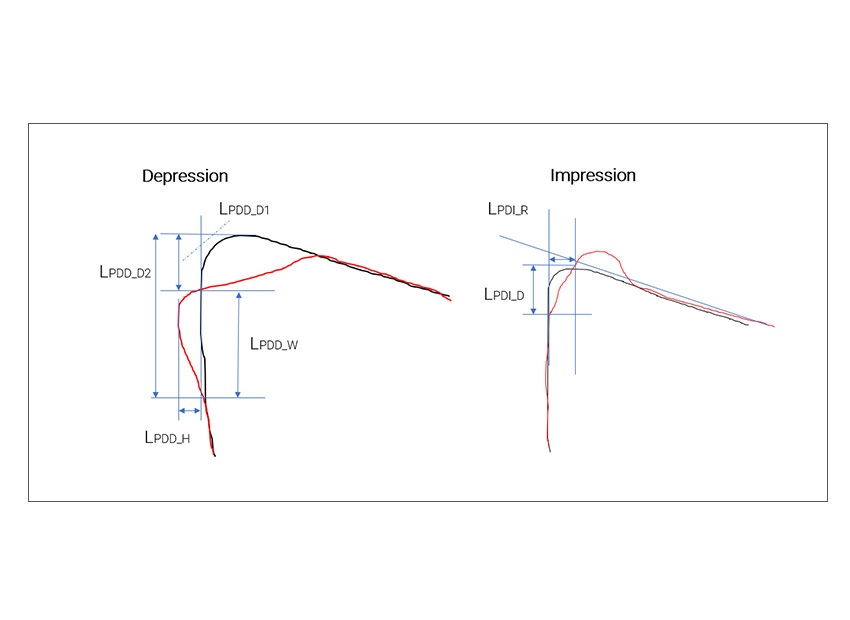

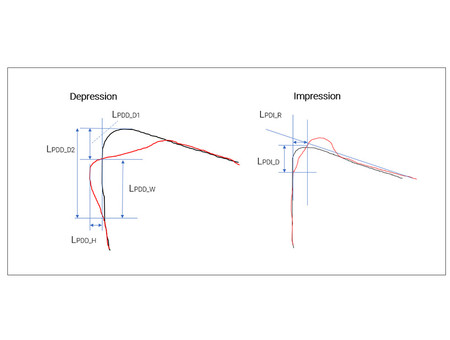

Automatic measurement of various wear parameters (e.g. flank wear, notch wear, plastic deformation)

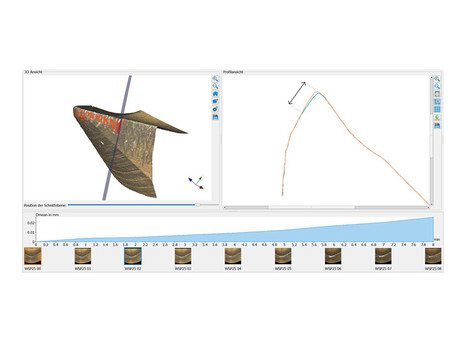

Visualization and animation of wear process (morphing)

Visualization of original and several worn surface profiles and 3D data sets

Export of results to .csv

Automatic measurement of various types of wear:

Users measure volume and area parameters, which are used to numerically determine the development of wear over a defined period of time. Based on this, types of wear such as flank wear, notch wear and plastic deformation can be determined. In conjunction with the automation interface "Automation Manager", measurement series for different tool types can be automatically configured, executed and organized.

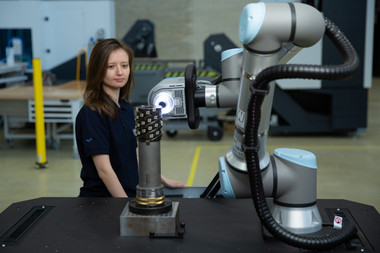

Wear Measurement in the cutting tooling industry

Leading tool manufacturers worldwide use Bruker Alicona for quality assurance of tools and cutting edges. The product range includes fully automatic measuring solutions in production and comprehensive analysis modules including visualization. Measuring systems can be operated without prior knowledge of metrology. Taught-in measuring programs are started at the push of a button; the user has no influence on the measuring result. All measurements are high-resolution, traceable and repeatable.