Detection of smallest differences in roughness

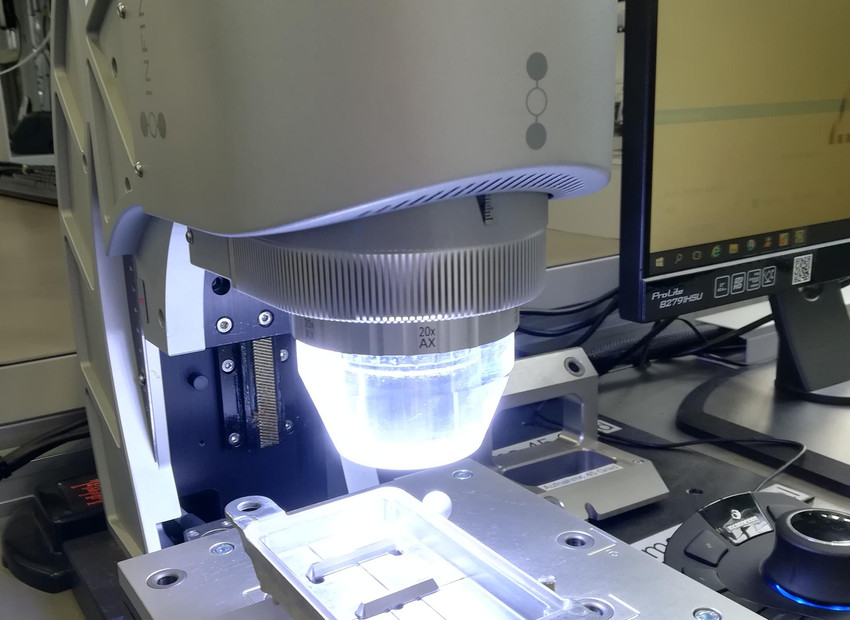

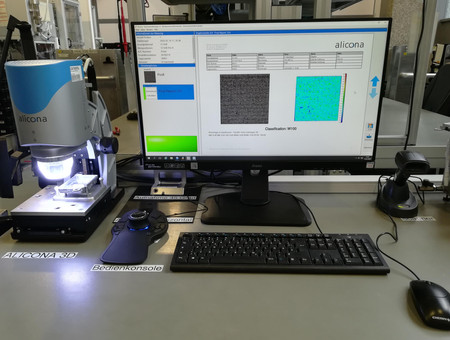

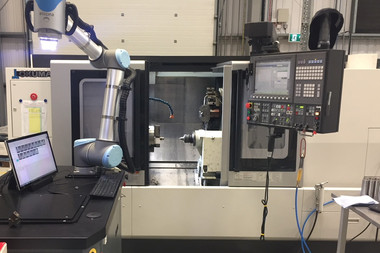

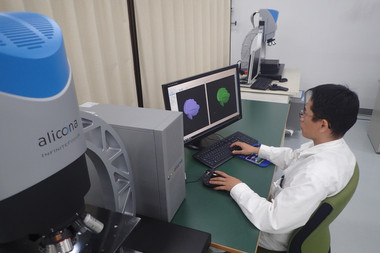

For the implementation of a new laser cleaning process, Vitesco Technologies, formerly Continental Division Powertrain was looking for a measuring device to monitor the performance and quality of laser processing in series production. The automotive supplier found it in a Bruker Alicona 3D measuring system. In addition to the 3D topography measurement, this offers a new classification software. Based on AI, the software automatically detects OK and not OK surfaces.

Hermann Hämmerl

Senior Process Engineer

The surface produced by laser has an influence on the durability of the bonding, and 3D measurement technology should help to ensure the long-term function of the sensor in vehicle operation.

READ THE ENTIRE SUCCESS STORY

Optical 3D measurement technology to ensure long-term function of sensors in vehicle operation

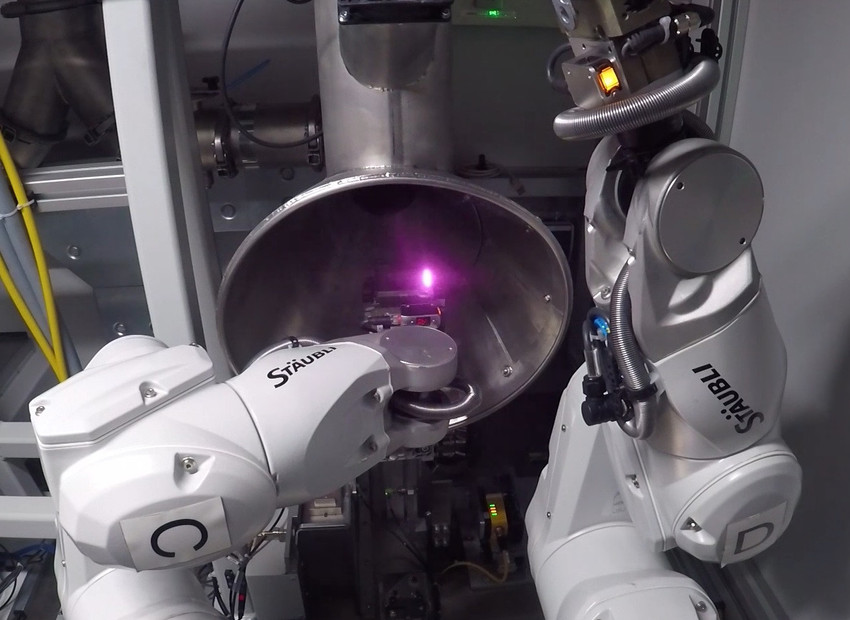

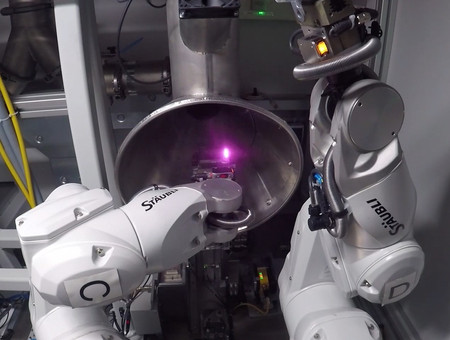

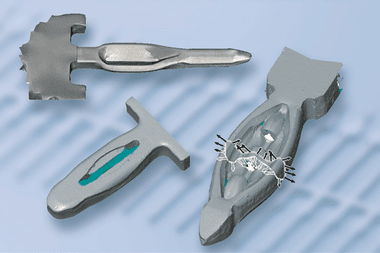

The core of every vehicle is its powertrain system. This is what Vitesco Technologies stands for, specialized in the production of modern powertrain technologies for clean and sustainable mobility. Optimized technologies that contribute to the reduction of nitrogen emissions (NOx) can be implemented, among other things, through intelligent solutions in exhaust gas aftertreatment. This also includes the development of NOx exhaust gas sensors, which sometimes pass through critical process steps in production. A critical process step is the application of modern cleaning technologies in which a surface is processed, e.g. by means of pulsed laser radiation and thus prepared for the following processes. "Technical Cleanliness and Cleaning Technologies" is the area of expertise of Hermann Hämmerl, Senior Process Engineer in the Central Manufacturing Technologies department of the Business Unit Sensing & Actuation (Regensburg). He coordinates process development for new technologies through to their introduction in the German automotive supplier's worldwide network of plants. This also includes "searching for methods that allow the process results to be verified," he explains.

In this specific case, Hämmerl was responsible for the implementation of a new laser cleaning process that is intended to prepare die-cast surfaces for subsequent bonding to the electronics housing of a NOx exhaust gas sensor. The surface produced by laser has an influence on the durability of the bonding, and 3D measurement technology should help to ensure the long-term function of the sensor in vehicle operation.

How Vitesco succeeds with Bruker Alicona solution

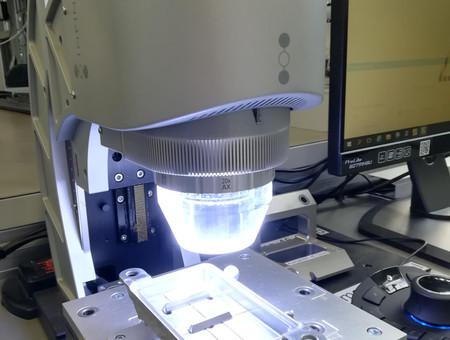

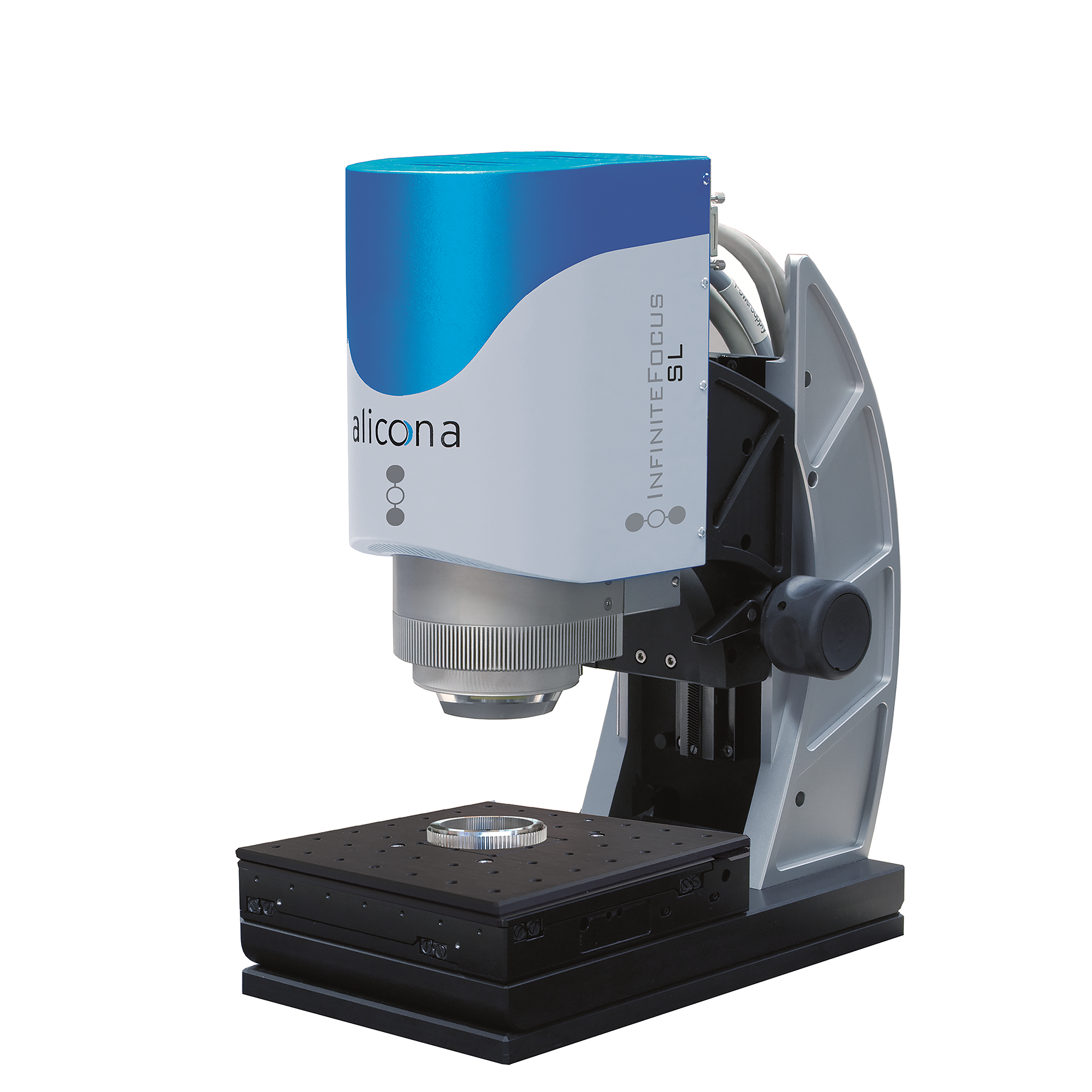

InfiniteFocus SL

3D measurement system for form & finish

- Easy, fast and traceable measurement of form and finish on micro structured surfaces

- Users measure both form and roughness of components with only one system

- With an automation interface, InfiniteFocusSL is also applied for fully automatic measurement in production